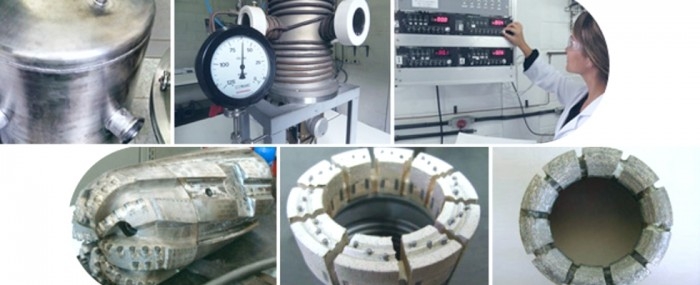

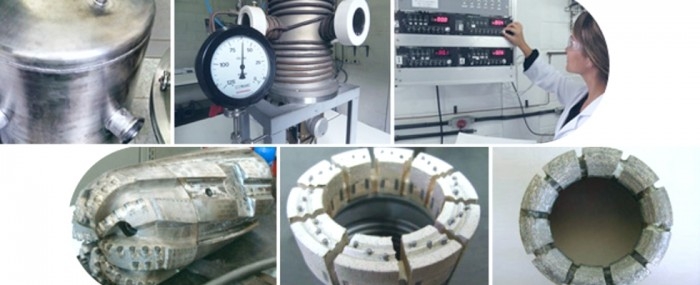

CVDVale, a Brazilian company based in São Paulo State, produces high-strength synthetic diamonds and diamond-like carbon coatings for use in the oil, mining and automotive industries, and in medical and dental equipment (photos: CVDVale)

CVDVale, a Brazilian company based in São Paulo State, produces high-strength synthetic diamonds and diamond-like carbon coatings for use in the oil, mining and automotive industries, and in medical and dental equipment.

CVDVale, a Brazilian company based in São Paulo State, produces high-strength synthetic diamonds and diamond-like carbon coatings for use in the oil, mining and automotive industries, and in medical and dental equipment.

CVDVale, a Brazilian company based in São Paulo State, produces high-strength synthetic diamonds and diamond-like carbon coatings for use in the oil, mining and automotive industries, and in medical and dental equipment (photos: CVDVale)

By Simone Mateos | FAPESP Research for Innovation – Trading as CVDVale, Clorovale Diamantes Indústria e Comércio, a Brazilian company based in São Paulo State, produces high-strength synthetic diamonds (CVD, which stands for crystals formed through Chemical Vapor Deposition) with the same physical and chemical properties as natural diamonds, as well as diamond-like carbon (DLC) coatings for use in the oil, mining and automotive industries, and in medical and dental equipment.

CVDVale was founded in 1997, when a group of researchers affiliated with the National Space Research Institute (INPE), in Brazil, won a grant from FAPESP’s Innovative Research in Small Business Program (PIPE) to fund the development of diamond tips for ultrasonic dental drills.

The results of its research put the firm among the pioneering producers of ultrasonic dental drills and tips. The CVDentus technology enabled it in 2009 to join a group of 36 startups selected to receive investment financing from Criatec, a seed capital fund established by BNDES, the national development bank, with additional contributions from Banco do Nordeste do Brasil (BNB).

CVDentus is a technology for dental drill tips with bactericidal properties that enables ultrasonic drills to be used not only to remove caries without bleeding and practically without pain but also to drill alveolar bone in preparation for implants without the risk of injuring soft tissue. The device is almost soundless and requires no anesthetic in 70% of cases. The technology is patented and has won several awards, such as the 2003 prize for the best product in the Southeast Region from FINEP, the Brazilian Innovation Agency, and the 2011 prize in the category Innovative Inventor, as well as an award from the World Intellectual Property Organization (WIPO) for the world’s best inventions, also in 2011.

Like other innovations produced later by CVDVale, the origins of CVDentus date from the early 1990s, when the firm’s four founders – Vladimir Trava-Airoldi, Evaldo Corat, Luiz Gilberto Barreta and Luis Francisco Bonetti – began working to ensure that INPE, where they were employed as researchers, could master the technology to produce synthetic diamonds for use in satellites as heat sinks and solid lubricants.

One of their aims with this initiative, which was supported by FAPESP, was to found startups that would develop new applications for the technology, leveraging the unique properties of CVD diamonds. At that time, Trava-Airoldi had just returned to INPE after completing postdoctoral research in molecular physics at NASA. “I went there precisely to find out how they were able to convert the knowledge derived from space research into innovations with a broad social impact,” he says.

At INPE, the researchers succeeded in perfecting the technology to produce CVD diamonds and DLC film. The latter is made of a non-crystalline material with properties similar to those of CVD diamonds but with more industrial applications because it can be synthesized at lower temperatures, on larger surfaces, and on substrates typically used by manufacturers, such as steel, aluminum, brass, plastic and glass.

Friction coefficient

Trava-Airoldi explains that synthetic diamonds have the lowest friction coefficient of all solid materials coupled with high thermal conductivity, so that they are effective for rapid heating or cooling. They are excellent electrical insulators, but they can also serve as semiconductors depending on how they are doped. Other properties include a broad optical transmission spectrum, significant resistance to chemical corrosion, and biocompatibility. They also have bactericidal properties when doped with certain nanoparticles.

Their potential applications are therefore numerous, ranging from microelectronic appliances to cutting tools and anti-friction coatings in automotive and aircraft engines, parts and recipients used in the chemical industry, glass and ceramics processing, and the production of optical protection film, among many others.

The technology developed at INPE by the researchers increased the hardness of DLC, increased the speed at which CVD diamonds are synthesized, and greatly enhanced the adhesion of both materials to some of the substrates on which they are “grown”, such as molybdenum, steel and titanium, extending their industrial applications. The first was the use of DLC as a solid lubricant on the surfaces of satellite moving parts, where it performed far better than the imported materials used until then.

Dental applications came later, with FAPESP’s support via PIPE, which helped found CVDVale with the initial aim of developing diamond tips for ultrasonic drills.

It took five years for CVDVale to commercialize its first dental drill tip. Today the firm makes ultrasonic drills, tens of models of drill tips, and two burr shanks, one for alveolar bone and the other for teeth.

Orthopedic surgery

The results in dentistry encouraged the firm to develop another ultrasonic device for orthopedic surgery, in which the surfaces to be cut are much larger. The project, which is also supported by PIPE, is scheduled for completion in January 2018 and has already led to the launch of a new shank for dental surgery.

“For bone cutting, we’ve replaced diamond with DLC, which is cheaper and can be used in a wider, serrated cutting surface that’s far better for large incisions,” Corat explains.

Another focus for tooth and bone cutting technology still under development is enhancement of standardization for large-scale production. To this end, CVDVale has brought on board Deiler de Oliveira, a researcher who previously worked for a major copper mining company and a European Union project to standardize processes in different countries.

Since its inception, CVDVale has never ceased innovating, assisted by seven stages of PIPE and close collaboration with INPE. “Both sides benefit,” Trava-Airoldi says. “The firm advances thanks to the knowledge created at INPE, especially with the three Thematic Projects supported by FAPESP. And INPE’s research benefits from the knowledge created at CVDVale.”

The collaboration has already led to 12 patents and more than 250 scientific articles published in international journals, not to mention the world’s first courses in ultrasonic dentistry, delivered at the University of São Paulo (USP).

In addition to the products mentioned, CVDVale produces to order self-sharpening diamond bits for drilling water, gas and oil wells. It also coats any metal surface with DLC to enhance its strength, adhesion, corrosion resistance, solid lubrication, biocompatibility, bactericidal effects or anti-coagulant action, in accordance with the customer’s requirements, in all cases by including different nanoparticles in the coating.

Projects supported by FAPESP:

Development of devices in CVD diamond for short-term applications (1998-2002)

CVD diamonds for new high-performance drilling and cutting tools (2007-2010)

Ultrasound equipment for bone surgery with CVD diamond tips (2012-2013)

Ultrasound equipment for bone surgery with CVD diamond tips (2015-2017)

Read more at: revistapesquisa.fapesp.br/en/2009/11/01/eclectic-diamond

Company: CVDVale

Site: www.cvdvale.com.br

Address: Estrada Principal do Torrão de Ouro, 500, São José dos Campos, São Paulo

Tel: +55 12 3944 1126

Contact: comercial@cvdvale.com.br

Republish

The Agency FAPESP licenses news via Creative Commons (CC-BY-NC-ND) so that they can be republished free of charge and in a simple way by other digital or printed vehicles. Agência FAPESP must be credited as the source of the content being republished and the name of the reporter (if any) must be attributed. Using the HMTL button below allows compliance with these rules, detailed in Digital Republishing Policy FAPESP.