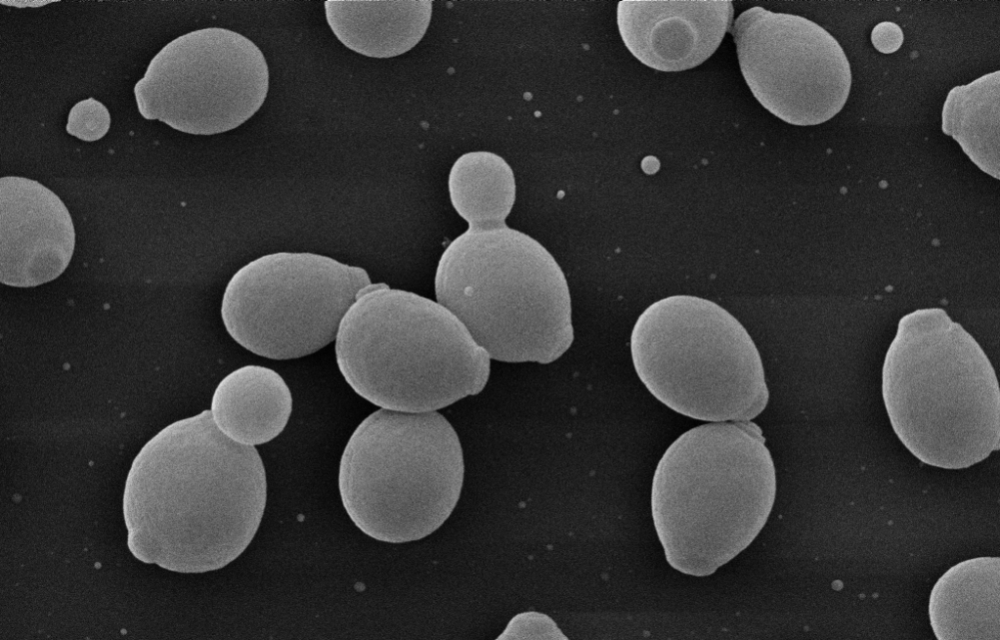

A particular yeast that is more resistant to the new conditions for industrial fermentation reduces the loss of sugar and the chance of contamination in addition to presenting other benefits (electron microscope image of the Fermel: Fermentec)

A particular yeast that is more resistant to the new conditions for industrial fermentation reduces the loss of sugar and the chance of contamination.

A particular yeast that is more resistant to the new conditions for industrial fermentation reduces the loss of sugar and the chance of contamination.

A particular yeast that is more resistant to the new conditions for industrial fermentation reduces the loss of sugar and the chance of contamination in addition to presenting other benefits (electron microscope image of the Fermel: Fermentec)

By Diego Freire

Agência FAPESP – A yeast that is adapted to the changes in the sugar and ethanol industrial production process – that is, the mandatory replacement of manual harvest by mechanized methods in the state of São Paulo – increases yield and reduces losses during fermentation compared to traditional yeast.

The yeast, which goes by the commercial name Fermel, was selected by Fermentec, an industrial technology company located in Piracicaba (SP) that specializes in alcohol fermentation, on the basis of studies that were developed with support from the FAPESP Technological Innovation in Small Business Program (PIPE). The innovation was presented at the Dialogue about Support to Innovation in Small Businesses sponsored by FAPESP on September 9, 2014, to answer any questions from those interested in taking part in the proposal selection under PIPE.

The purpose of the study was to obtain an industrial yeast that is better adapted to the new sugarcane harvest characteristics specified in the 2007 Agro-environmental Protocol of the Sugar and Ethanol Sector, which prohibits burning.

“The gradual replacement of manual sugarcane harvest in São Paulo by mechanized methods brings environmental benefits but also new challenges for the sugar and ethanol industrial production process,” Mário Lúcio Lopes, Fermentec’s Scientific Director, told Agência FAPESP.

This is because the sugarcane, which was once burned, now arrives at the plant raw, with needles, leaves, and soil. “These plant and mineral impurities that contaminate the sugarcane are harmful to fermentation,” Lopes says.

For effective fermentation, a yeast is needed that not only tolerates impurities but also suppresses wild yeast that is present in the raw sugarcane. “This is one of the characteristics of personalized and selected yeasts, which guarantee more suitable fermentation with higher yield,” he explained.

Yeasts transform sugarcane, which is a solid, into fuel alcohol, which is a liquid. In order to conduct the process more effectively, yeasts need to be suited to each medium.

“We studied and identified the relationship between yeast and industrial fermentation and found that the better adapted the yeast is to the industrial unit, the more efficient will be the fermentation, and as a result, the production,” Lopes said.

Innovative research

Derived from PE-2, a yeast that has been used in ethanol fermentation in Brazil since the 1990s, Fermel presents high tolerance to the new industrial processing conditions, say the producers.

Fermel reduces the possibility that wild yeasts will invade the process. Wild yeasts are responsible for problems such as the formation of foam, which takes up space in the tanks, and flocculation, which complicates fermentation. The development of Fermel involved the use of karyotyping techniques and the analysis of yeast mitochondrial DNA.

In karyotyping, yeasts are cultivated to form small colonies from which intact chromosomes containing genetic material are extracted. These chromosomes are then separated in an electric field.

“Variations in the size and number of chromosomes function as ‘fingerprints’ that allow the identification of selected yeasts and their differentiation from wild contaminants,” Lopez said.

During mitochondrial DNA analysis, small DNA molecules are extracted from the mitochondria of the yeasts and cut at specific points. “The fragments are then separated in an electric field, and the profile is used to identify the yeast, as if it were a barcode,” he said.

These analyses allow the selection of yeasts that are best suited to the industrial environment. Fermel was shown to be highly efficient in high-alcohol-content, molasses-rich wort, and in addition it dominates yeast populations, reducing the chances that contamination will occur during fermentation.

“The industry works with very large volumes, and it is difficult to eliminate these microorganisms, which can be wild yeasts or even bacteria. They manage to get into the fermentation and compete with the selected, good yeast. When [the good yeasts] are more resistant and adapted to that industrial fermentation condition, their population displaces less-robust yeast. Fermel is significantly more resistant and dominates the fermentation environment,” Lopes said.

Contamination from wild yeast causes a series of problems for industry, such as excess unfermented sugar, resulting in reductions in yield.

“It is a matter of wasted potential. That is why it is important to have a robust yeast that can reduce contamination problems and be good at fermenting so there is no leftover sugar, thus allowing a better outcome for the ethanol plant – especially now that burning has been eliminated,” Lopes said.

Republish

The Agency FAPESP licenses news via Creative Commons (CC-BY-NC-ND) so that they can be republished free of charge and in a simple way by other digital or printed vehicles. Agência FAPESP must be credited as the source of the content being republished and the name of the reporter (if any) must be attributed. Using the HMTL button below allows compliance with these rules, detailed in Digital Republishing Policy FAPESP.