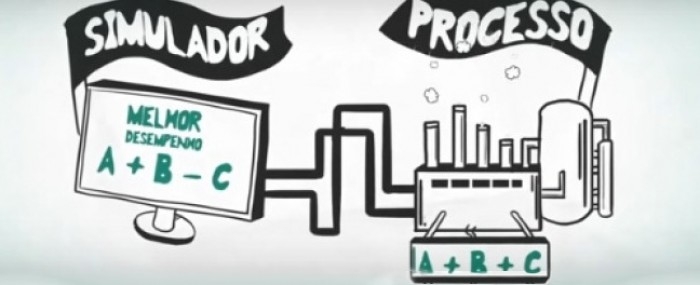

Taking into account the performance of every piece of equipment involved in producing sugar, ethanol and power, a simulator predicts final output and helps the industry calculate product mix (image: release)

Taking into account the performance of every piece of equipment involved in producing sugar, ethanol and power, a simulator predicts final output and helps the industry calculate product mix.

Taking into account the performance of every piece of equipment involved in producing sugar, ethanol and power, a simulator predicts final output and helps the industry calculate product mix.

Taking into account the performance of every piece of equipment involved in producing sugar, ethanol and power, a simulator predicts final output and helps the industry calculate product mix (image: release)

FAPESP Research for Innovation – In 2005, a computer engineer and a mechanical engineer with PhDs from the University of São Paulo (USP) in São Carlos, Brazil, decided to set up a firm that would offer technological solutions for the improvement of industrial processes in sugar and ethanol plants.

They held meetings with technicians from CTC Centro de Tecnologia Canavieira S.A. and found that the industry lacked a system to simulate production processes as an input for strategic decision making on such matters as choosing the product mix – sugar, ethanol and power generation – based on the volume of sugarcane processed or the market value.

“We realized the solution was to create a virtual plant to simulate the entire production line, from cane crushing to end-product, so that mills could analyze mass-energy balance,” explains Claudio Adriano Policastro, a partner in the firm.

In 2006, Policastro and André Ribeiro Lins de Albuquerque founded Atenatec Soluções Tecnológicas, now known by the brand name Pentagro, which was initially incubated at CEDIN (Centro de Desenvolvimento de Indústrias Nascentes) in São Carlos.

In 2008, they succeeded in winning approval for two projects under FAPESP’s Innovative Research in Small Business Program (PIPE). The first was for the development of a system to simulate mass-energy balance, and the second was for advanced industrial process control based on neural networks.

Following the development stage and the commercialization of the first units, the advanced control project was temporarily suspended. The firm concentrated attention on the virtual plant, which was extended to simulate processes not just in distilling but throughout the industry.

The virtual plant came to market under the name Simulador Pentagro. The system uses a set of mathematical models to simulate all the processes involved in producing sugar, ethanol and power. “Each piece of equipment in the industry has an equivalent in the system,” Policastro says. As a result, the system predicts the performance of boilers or power generation turbines, for example, during the processing of sugarcane by a mill, pointing out bottlenecks and estimating energy consumption and water usage, for example. “The simulation also predicts the amount of sugar, ethanol or power that will be produced from a given amount of processed sugarcane with specific characteristics in terms of fiber, sugar content, purity, and so on.”

Pentagro has now expanded its portfolio with a new product embodying the technology, called Pentagro PGDI Online. The acronym stands for Daily Production Planning and Industrial Performance Management. The platform can be used to monitor the entire production chain online using the Pentagro simulator, as well as to simulate the production of second-generation ethanol.

The Pentagro simulator and especially PGDI Online have drawn attention from the market and driven growth for the firm. Pentagro PGDI Online is already used in one of 11 plants operated by Biosev (Louis Dreyfus Group), in one of Raízen’s 23 plants and one unit of Usina Santa Adélia, and by Usina Ferrari and Usina Santa Cruz. In addition, the Pentagro simulator is used in all seven Guarani plants and by Usina São Martinho and Petrobras Biocombustíveis. In 2015, Pentagro reported sales of R$629,000. For 2017, it forecasts sales of R$1.29 million.

Pentagro Soluções Tecnológicas

Site: pentagro.com.br/pentagro_novo

Address: Passeio dos Flamboyants, 60 Ed. Tríade - Torre São Paulo - Sala 80, São Carlos (SP), Brazil

Tels: +55 16 3351-0203 and +55 16 3412-9531

Contact: contato@pentagro.com.br

Republish

The Agency FAPESP licenses news via Creative Commons (CC-BY-NC-ND) so that they can be republished free of charge and in a simple way by other digital or printed vehicles. Agência FAPESP must be credited as the source of the content being republished and the name of the reporter (if any) must be attributed. Using the HMTL button below allows compliance with these rules, detailed in Digital Republishing Policy FAPESP.