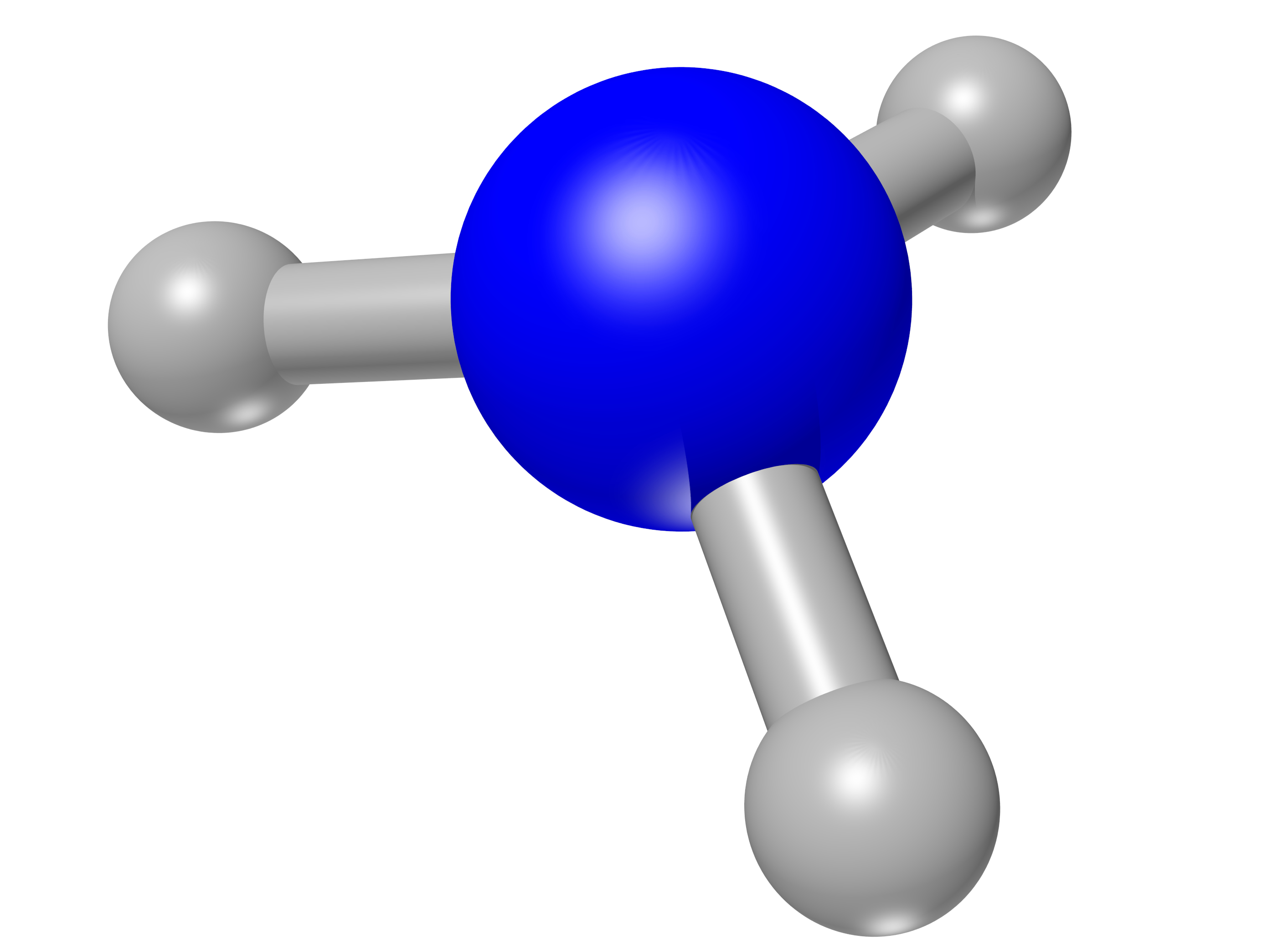

Ammonia (NH3) is one of the most synthesized molecules in the world and is essential for producing fertilizers (image: Colin Behrens/Pixabay)

The chemical compound is used in various industrial processes, but its synthesis is highly polluting. Research involving scientists from the Center for Development of Functional Materials and the Center for Innovation on New Energies, supported by FAPESP, indicates clean ways of obtaining the input.

The chemical compound is used in various industrial processes, but its synthesis is highly polluting. Research involving scientists from the Center for Development of Functional Materials and the Center for Innovation on New Energies, supported by FAPESP, indicates clean ways of obtaining the input.

Ammonia (NH3) is one of the most synthesized molecules in the world and is essential for producing fertilizers (image: Colin Behrens/Pixabay)

Agência FAPESP* – Three studies involving researchers from the Center for Development of Functional Materials (CDMF) and the Center for Innovation on New Energies (CINE), both in the state of São Paulo, Brazil, have developed sustainable methods for producing ammonia. Ammonia is widely used in different chemical processes and as a fertilizer worldwide. However, traditional production methods are highly polluting.

The CDMF is a FAPESP Research, Innovation, and Dissemination Center (RIDC) based at the Federal University of São Carlos (UFSCar). The CINE is an Applied Research Center (ARC) supported by FAPESP and Shell.

One of the studies was conducted in partnership with researchers from the University of Bath in the United Kingdom. The study was published in an article in Green Chemistry, a journal published by the Royal Society of Chemistry, a British institution. The study details the development of a molybdenum disulfide (MoS₂) catalyst modified with a microporous polymer called PIM-1 to produce ammonia more cleanly and efficiently.

This technique enables the direct generation of ammonia from nitrogen in the air under ambient conditions, eliminating the need for high pressures or temperatures. Using the electrochemical process, the researchers obtained nearly double the production when molybdenum disulfide was modified with the polymer, in addition to achieving 45% energy efficiency. The material’s effectiveness in the presence of oxygen is innovative because it broadens its practical applications.

Lucia Mascaro, a researcher at the CINE and the CDMF and one of the authors of the article, said the approach “represents an important step toward decentralized and sustainable fertilizer production.” She also pointed out that the technology can be integrated with solar energy sources and that the study confirms the viability of new technological routes to reduce carbon emissions in the chemical industry.

The second study was published in the article “Multi-layer kesterite-based photocathodes for NH3 photosynthesis from N2 reduction reaction”, which was chosen for the cover of ChemPhysChem. It presents a strategy for the sustainable production of ammonia using sunlight. The team developed a multilayer photocathode composed of kesterite, cadmium sulfide, and titanium dioxide, which was decorated with platinum nanoparticles and applied to the nitrogen reduction reaction via photoelectrocatalysis. The material showed excellent performance, with production 28 times higher than that obtained without platinum. The technique was also superior to the photocatalytic and electrocatalytic approaches used in isolation. This is the first time that a kesterite-based photocathode has been used successfully for ammonia production.

The third study describes the development of an electrocatalyst consisting of an amorphous nickel phosphide electrode that is deposited by electrodeposition and surface-modified with iron oxyhydroxide. This electrocatalyst is used to recover nitrogen from industrial and agricultural effluents by electrocatalytically reducing ammonium nitrate. The work was published in an article in the Journal of Materials Chemistry A.

“The three research fronts converge to demonstrate new, clean, and efficient routes for ammonia production,” says Mascaro. "Together, these approaches – advanced electrochemistry, photoelectrocatalysis, and nitrate recovery – reinforce the viability of decentralized methods powered by renewable energy to replace the Haber-Bosch process and significantly reduce the carbon footprint in fertilizer production."

* With information from the CDMF

Republish

The Agency FAPESP licenses news via Creative Commons (CC-BY-NC-ND) so that they can be republished free of charge and in a simple way by other digital or printed vehicles. Agência FAPESP must be credited as the source of the content being republished and the name of the reporter (if any) must be attributed. Using the HMTL button below allows compliance with these rules, detailed in Digital Republishing Policy FAPESP.