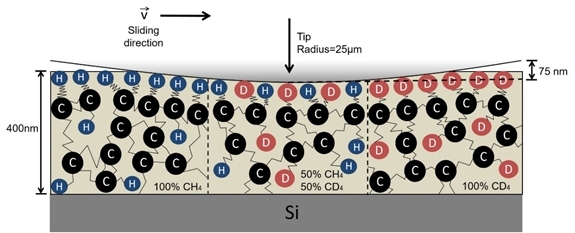

Schematic of the system used in the experiment. The figure shows the crystalline silicon substrate, the material studied (400 nm), and the diamond tip sliding from left to right. The material was an amorphous carbon with different proportions of hydrogen (H) and deuterium (D), increasing from left to right. The springs represent C-H and C-D bonds. Friction is lower in the material with larger proportions of D due to a decreased coupling between the tip and vibrations (phonons) in C-D from that i

Researchers calculated the role of vibrations that propagate in crystalline networks of materials in friction. This study may lead to technological solutions to decrease wear and enhance the efficiency of devices.

Researchers calculated the role of vibrations that propagate in crystalline networks of materials in friction. This study may lead to technological solutions to decrease wear and enhance the efficiency of devices.

Schematic of the system used in the experiment. The figure shows the crystalline silicon substrate, the material studied (400 nm), and the diamond tip sliding from left to right. The material was an amorphous carbon with different proportions of hydrogen (H) and deuterium (D), increasing from left to right. The springs represent C-H and C-D bonds. Friction is lower in the material with larger proportions of D due to a decreased coupling between the tip and vibrations (phonons) in C-D from that i

By José Tadeu Arantes | Agência FAPESP – Friction is a ubiquitous phenomenon in everyday life. Among many other examples, we can walk only because of the friction between our feet or shoes and the ground. The sense of touch depends on friction between the hands or other parts of the body and other objects. The macroscopic study of friction began with Leonardo da Vinci (1452-1519), a Renaissance genius and polymath who established the “natural law” that can be written in current mathematical language as F = μ.N, where F is the force of friction between two sliding surfaces, μ is the coefficient of friction, and N is the normal force between surfaces.

The atomic force microscope (AFM) was invented in the 1980s to investigate and measure atomic-scale friction. An AFM scans the structures of a surface in great detail by using a diamond tip applied with minimal pressure to the sample. Another frequently used instrument for mesoscopic and nanoscopic measurements is the nanoindenter, a diamond tip that slides over the substrate being studied, with its pressure and speed controlled by electric and magnetic devices, and continuously records the tangential forces due to friction.

Using a nanoindenter, researchers at three Brazilian universities (the University of Caxias do Sul, UCS; the University of Campinas, UNICAMP; and the Pontifical Catholic University of Rio de Janeiro, PUC-RJ) have studied the role of phonon dissipation via vibrations propagating in the material’s crystalline network in friction. The study resulted in the article “On the phonon dissipation contribution to nanoscale friction by direct contact,” published in Scientific Reports, an online journal owned by Springer Nature.

The initiative for the study came from Carlos Alejandro Figueroa, a researcher affiliated with UCS, which has the necessary equipment for this experiment. Figueroa recruited two additional colleagues: Fernando Alvarez at UNICAMP, who supervised Figueroa’s PhD and postdoctoral research, and Fernando Lázaro Freire Jr. at PUC-RJ, both of whom are experienced in the fabrication and physicochemical characterization of carbon-based thin films.

The study was supported by FAPESP via the Thematic Project “Research and development of nanostructured materials for electronic and surface physics applications”, with Fernando Alvarez as principal investigator.

“When you go down to the atomic level, you have to take into account the electric, magnetic and contact forces between atoms, but phonons are also an important energy dissipation mechanism. When two surfaces slide against each other, the molecules in the materials vibrate. These vibrations, which can propagate in crystal structures, are called phonons. Our study focused on this specific phenomenon,” Alvarez told Agência FAPESP.

A phonon is a mechanical excitation that propagates through the crystalline network of a solid. In classical physics, this excitation can be described as an elastic wave, but when the phenomenon occurs at the atomic scale, it is necessary to use quantum physics. In this case, a phonon should be thought of as a quantum of energy traveling through the network.

“Our first challenge was to isolate this factor from others that occur at the same scale, meaning electric, magnetic and contact interactions, in order to determine its specific contribution to friction,” Alvarez said. “So we thought of comparing materials with the same electric, magnetic and contact properties but different phonon properties.”

To do this, the researchers deposited a nanometric layer of diamond-like carbon (DLC) on a crystalline silicon substrate. DLC is extremely hard and virtually inert. It has a low coefficient of friction and is fairly well known for its use as a protective film in macroscopic and nanoscopic mechanisms, especially in high-efficiency engines, such as those used in Formula 1 and NASCAR racing cars. However, in this study, the researchers substituted deuterium for some or all of the DLC’s hydrogen atoms.

A hydrogen atom has one proton (in the nucleus) and one electron (in the outer layer). Deuterium is an isotope of hydrogen with a neutron and a proton in its nucleus. Deuterium is therefore chemically identical to hydrogen. The chemical properties of atoms depend only on the outer electron layer, and this layer is the same in both isotopes. These two atoms are also identical in electric and magnetic terms, because these properties depend on the charge.

However, deuterium has approximately twice the mass of hydrogen because of the extra neutron.

“With double the mass, deuterium vibrates at a lower frequency than hydrogen when bonded to a heavy atom such as carbon. More precisely, the frequencies at which the two isotopes vibrate are inversely proportional to the square roots of the respective masses,” the coordinators of the study said.

Using the nanoindenter’s diamond tip, the researchers calculated the force required to scratch layers of DLC with different atomic compositions: carbon and hydrogen (C-H), carbon and hydrogen (C-H) plus carbon and deuterium (C-D), and carbon and deuterium (C-D). “We demonstrated that friction force clearly decreases as the percentage of deuterium in the composition increases. The only factor that can account for this decrease in friction force is the increase in the mass of the material and hence the decrease in vibration frequency,” they explained.

With this experiment and its simple design but sophisticated execution, the researchers have succeeded in isolating phonon interactions from electric, magnetic and contact interactions and in calculating the specific contribution of phonon interactions to the phenomenon of friction. “Following a theoretical adjustment to the possible models of phonon excitation, the results obtained converged with the random distribution of deuterium atoms in a DLC matrix,” Alvarez said.

The experiment suggests an obvious technological application: introducing deuterium into the alloy as a coating capable of mitigating the wear and tear of mechanical parts and increasing the efficiency of sliding mechanisms to enhance the DLC’s properties. The problem is cost.

Deuterium exists in nature, mainly in heavy water molecules comprising one oxygen atom and two deuterium atoms (D2O). Heavy water can be found in mountain lakes as well as other places. Because it is effective at slowing down neutrons, it is used as a moderator in some types of nuclear reactors. It is also used in underground tanks designed to capture neutrinos. However, the available supply of deuterium is very small: ordinary water contains approximately 150 deuterium atoms per million hydrogen atoms. Hence, cost is a constraint for the large-scale use of the material.

“But for nanometric devices, which require a tiny amount of material, the use of deuterium in protective films shouldn’t be ruled out,” Alvarez said. “What’s more, there are alternative ideas, such as introducing other elements, which could mitigate friction in the system at reasonable cost, based on the same principle.”

The phenomenon of friction is associated with the dissipation of energy as heat – or the conversion of mechanical energy into thermal energy. A trivial example is the habit of rubbing one’s hands together to warm them up on a cold day. They get warm because of friction between them: the mechanical energy of the friction is converted into heat. In this case, the conversion is positive, but in the case of applications such as machines, motors, and engines, the dissipation of energy as heat is a loss of efficiency, representing the other side of the coin. “US researchers estimate that some US$200 billion is lost every year in their country, owing to energy dissipation by friction, hence the interest in going beyond lubricants. Deuterium suggests a new technological horizon,” Alvarez said.

In addition to the three coordinators, Saron Sales de Mello (UCS), Marcelo Maia da Costa (PUC-RJ), Caren Machado Menezes (UCS) and Carla Daniela Boeira (UCS) also took part in the research.

Republish

The Agency FAPESP licenses news via Creative Commons (CC-BY-NC-ND) so that they can be republished free of charge and in a simple way by other digital or printed vehicles. Agência FAPESP must be credited as the source of the content being republished and the name of the reporter (if any) must be attributed. Using the HMTL button below allows compliance with these rules, detailed in Digital Republishing Policy FAPESP.