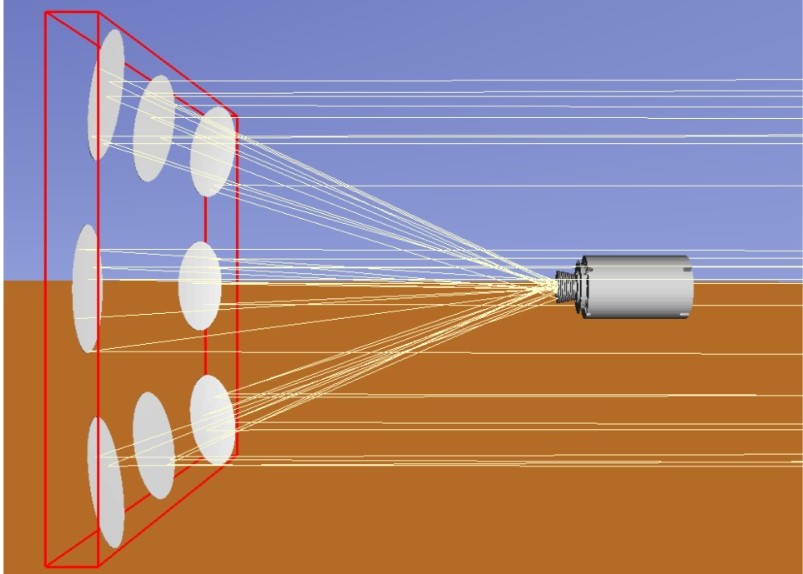

Schematic of the thermoluminous beam simulator (figure: José Roberto Simões Moreira)

Produced at the Engineering School (POLI-USP), the equipment generates thermal radiation similar to that of the sun. It makes it possible to test devices and technologies in the laboratory without having to rely on ideal weather conditions.

Produced at the Engineering School (POLI-USP), the equipment generates thermal radiation similar to that of the sun. It makes it possible to test devices and technologies in the laboratory without having to rely on ideal weather conditions.

Schematic of the thermoluminous beam simulator (figure: José Roberto Simões Moreira)

By José Tadeu Arantes | Agência FAPESP – The indoor solar simulator is a piece of equipment designed to artificially simulate solar radiation in controlled environments. It is used to test devices and technologies that use solar radiation, such as thermochemical reactors, steam generation and hot oils, among others. High-intensity xenon lamps emit light that is reflected and concentrated by parabolic mirrors, creating a thermoluminous beam similar to that of the sun. This allows tests to be performed without the need for ideal external weather conditions, such as clear skies without clouds.

Researchers at the Engineering School of the University of São Paulo (POLI-USP) in Brazil have developed and tested a new high-flow indoor solar simulator designed to optimize high-temperature thermal processes and improve concentrated solar power technologies. The work was carried out at the Alternative and Renewable Energy Systems Laboratory (SISEA). The simulator is now operational and can be used in various applications, such as thermochemical reactions to produce hydrogen and synthesis gas (a mixture of hydrogen and carbon monoxide with a high energy value); research on catalysts to optimize chemical reactions; casting of metals and other materials that require high temperatures; tests in solar ovens for industrial processes, etc.

“Our simulator uses eight high-temperature xenon arc lamps. The light emitted is reflected by a set of parabolic mirrors that produce collimated beams of radiation, that is, with parallel rays. These beams fall on a second set of parabolic mirrors to be concentrated at a common focal point, allowing intense solar conditions to be simulated inside the laboratory. The main objective of creating this ‘artificial sun’ is to allow controlled indoor experiments, overcoming the dependence on natural solar radiation, which is always subject to the diurnal cycle and climatic variations,” says researcher José Roberto Simões Moreira, full professor at POLI-USP, coordinator of SISEA and the main person responsible for the work in question.

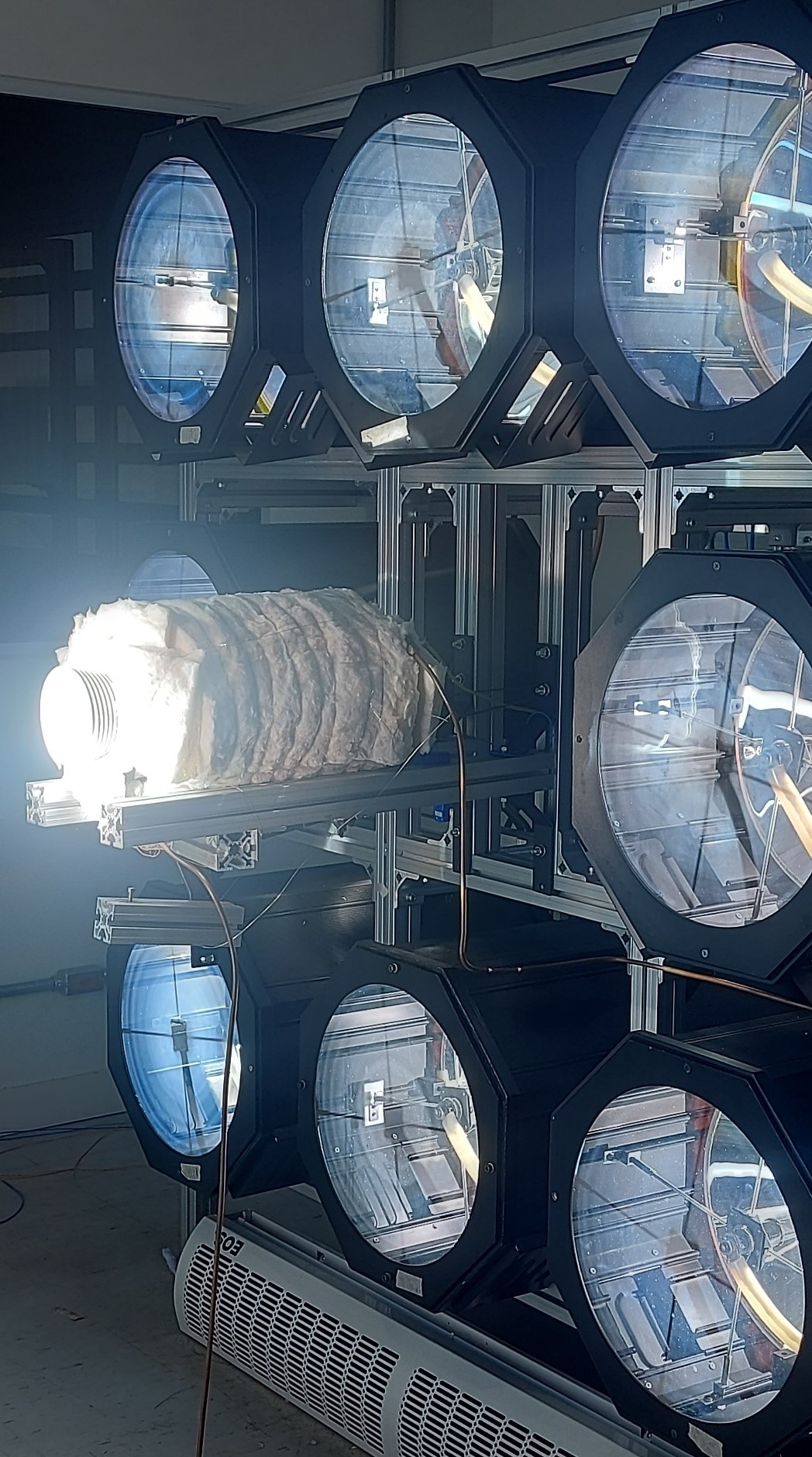

The thermoluminous radiation is generated by eight high-temperature xenon arc lamps. After being collimated and concentrated by parabolic mirrors, the final radiation is absorbed in a black cavity (photo: José Roberto Simões Moreira)

The work was supported by FAPESP through the project “Production of solar fuels from concentrated solar energy”. An initial presentation of the results was made in an article published in the journal Applied Thermal Engineering.

The reactions take place in a thermochemical reactor based on the concept of a “black cavity,” installed in the common focus of the reflecting mirrors, in which the concentrated radiation is absorbed and can reach temperatures of over 2,000 °C. These conditions are ideal for carrying out specific chemical reactions, such as the production of hydrogen gas through the oxidation-reduction process of metals. In this case, the process takes place in two stages: in the first, a metal is oxidized in the presence of water vapor, releasing hydrogen gas; in the second, the oxidized metal is reduced for reuse, closing the cycle. Alternatively, the equipment also makes it possible to produce synthesis gas by reacting methane (CH₄) with water vapor (H₂O) to form carbon monoxide (CO) and hydrogen (H₂), a process widely used in industry. Other reactions can also take place, for example using biomass as a raw material.

Simões says that the main difference between POLI-USP’s new simulator and other equipment of its kind is the use of secondary parabolic mirrors. “They reflect the collimated rays towards the focus of the master parabolic mirror, allowing more realistic conditions for laboratory tests and possible outdoor applications, unlike what happens with traditional ellipsoidal reflectors,” he says.

Special safety measures were taken to ensure the integrity of the operators. To avoid the risk of exploding lamps, a plate connected to a cooling system keeps the system temperature within a safe range. In addition, each lamp is protected by a front glass window that prevents accidental exposure to ultraviolet emissions and prevents flying debris in the event of an explosion. A locking system allows the light sources to be turned on and off from outside the test room. And each lamp is individually controlled, allowing the amount of irradiation on the target to be adjusted as needed. In addition, the entire set is installed in a room equipped with an interlocking system so that if anyone enters the room during operation, the entire set of lamps is turned off. This is because exposure to concentrated thermal radiation from the lamps can be fatal, especially in the vicinity of the main focus.

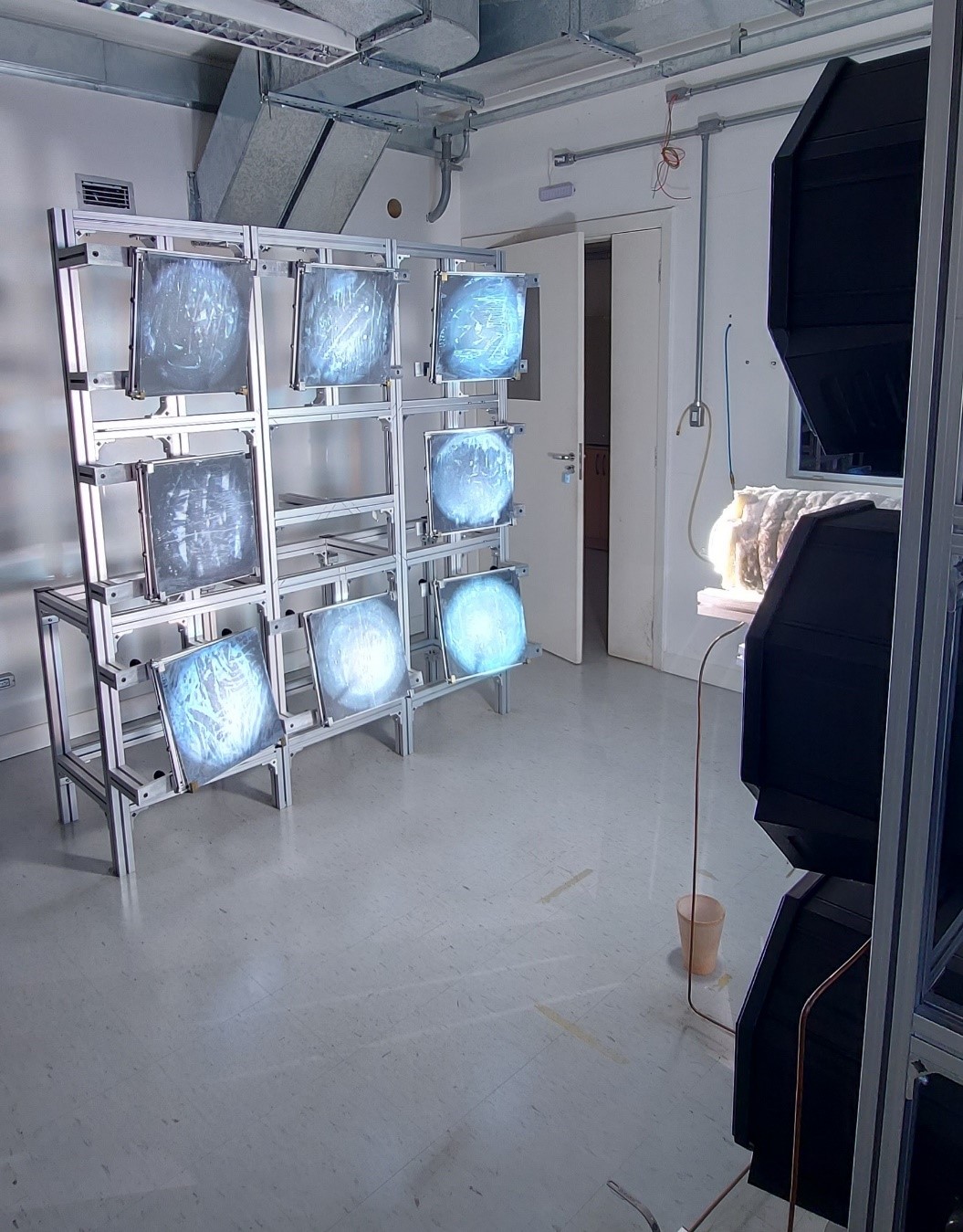

The set of parabolic mirrors that collimate and concentrate the thermoluminous rays (photo: José Roberto Simões Moreira)

The study used computational techniques (Monte Carlo method) to track the rays, simulate the optical path of the light and quantify the efficiency of the system. Experimental measurements were made using a spectrophotometer and a heat flow sensor to determine the concentrated thermal power and map its distribution.

“The simulator is already up and running, and the next step is to enable thermochemical reactions inside the black cavity. To this end, our group is focusing on catalyst research. In addition, we’re studying how to adapt the technology for external applications, using solar radiation directly instead of light bulbs. There’s great potential for applications in industry and in the production of clean fuels, steam and thermal energy cycles,” emphasizes Simões.

The article “Novel high-flux indoor solar simulator for high temperature thermal processes” can be read at www.sciencedirect.com/science/article/abs/pii/S1359431123012176.

Republish

The Agency FAPESP licenses news via Creative Commons (CC-BY-NC-ND) so that they can be republished free of charge and in a simple way by other digital or printed vehicles. Agência FAPESP must be credited as the source of the content being republished and the name of the reporter (if any) must be attributed. Using the HMTL button below allows compliance with these rules, detailed in Digital Republishing Policy FAPESP.