Safeguard for probiotics

Study shows that capsules covered in whey protein may protect lactobacilli against acid in the digestive tract, improving their potentially improving their efficacy.

Safeguard for probiotics

Study shows that capsules covered in whey protein may protect lactobacilli against acid in the digestive tract, improving their potentially improving their efficacy.

Study shows that capsules covered in whey protein may protect lactobacilli against acid in the digestive tract, improving their potentially improving their efficacy

By Flora Serra

Agência FAPESP – Lactobacilli are live organisms that, when administered in the right quantity, prove beneficial to the digestive and immune systems. The problem is that these probiotic organisms are also sensitive to the acid in the stomach itself.

Scientists at the Universidade Estadual de Campinas’ School of Food Engineering (FEA-Unicamp) have studied ways to protect lactobacilli during digestion so as to facilitate the beneficial effects of the bacteria.

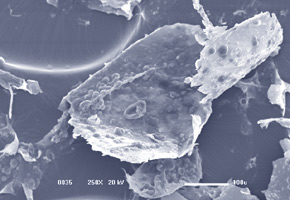

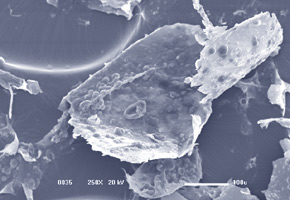

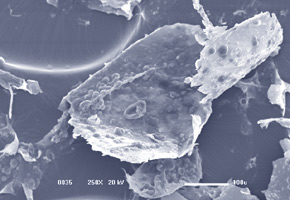

One recent study carried out at the university showed that capsules of probiotics covered in whey protein withstand passage through the digestive tract. The study investigated the microencapsulation of Lactobacillus acidophilus and its application in the manufacture of probiotic foods.

“We performed the study on two fronts: exploring the physico-chemical characteristics of the microcapsules, and also evaluating their application in the manufacture of yogurt and prato cheese,” said professor Mirna Lúcia Gigante, who coordinated the study. Students and FEA-Unicamp professor Carlos Grosso contributed to the work, which received FAPESP funding.

In the first part of the project, the group evaluated the process of covering pectin microcapsules in whey protein through electrostatic interaction. According to Gigante, the protein’s adsorption—the process through which molecules are fixed to a solid surface—to the surface of the capsules was greater when the whey protein had been heat treated.

According to Gigante, when exposed to artificial intestinal fluid in experiments simulating the digestive system in human intestines, the microcapsules coated with whey protein dissolved more easily than the particles made of pectin alone.

“We analyzed the maintenance of the probiotic’s viability, both free and in capsules, during food processing and also its preservation and resistance to the voyage through the gastrointestinal tract,” said Gigante.

This experiment was performed because the microorganisms should neither interfere with the processing nor change the characteristics of the food. In other words, they cannot in any way modify the food. “They can’t have any texture, odor, flavor or color,” said Gigante. The probiotic must also be able to survive the high acidity of the gastric region.

For yogurt, the researchers observed that microencapsulation of the probiotic kept it viable inside the product for 35 days of refrigerated storage.

When subjected to the intestinal fluid, the protective whey protein coating also showed positive results. “In total, 62% of the encapsulated probiotics survived. Without protection, only 10% of the free organisms survived,” said Gigante.

In yogurt production, when L. acidophilus was microencapsulated, the product showed less postacidification than the unencapsulated probiotic. This result means that the product’s desirable characteristics were not drastically altered.

However, the effects of microencapsulation were not the same for prato cheese. “The particle didn’t show any additional protective effect on the probiotic during storage or when subjected to conditions that simulate travel through the gastrointestinal tract,” said Gigante.

According to Gigante, it appears that the cheese’s natural protein complex already serves the function of protecting the microorganisms and keeping them alive.

“Still, the results made us want to further study the effects of different probiotics on the physico-chemical, microbiologic and sensory characteristics of the cheese,” said Gigante. Her team has analyzed a mixture of the two most commonly used probiotics in the dairy industry: L. acidophilus and Bifidobacterium.

New research

The study began in 2008 with the collaboration of Argentine researchers, including Carla Gerez from the Centro de Referência para Lactobacilos de Tucumán in Argentina, who did part of her doctoral studies at FEA-Unicamp.

“We did our first work with probiotic microencapsulation at that time. Together with professor Carlos Grosso, a microencapsulation specialist, we used the ionic gelation and complex coacervation technique, applying layers of pectin and whey protein as protective materials,” said Gigante.

The study showed that after exposure to gastric acid, Lactobacillus rhamnosus—the probiotic used—survived longer when it was wrapped in microparticles with whey protein layers than when it was free in the artificial digestive system.

“When it’s encapsulated, the microorganism is resistant to passage through the gastrointestinal tract and arrives at the final destination of the intestine, where it can be adsorbed. The microcapsule serves to protect the microorganism so it can make its way more effectively through the digestive system,” said Gigante.

In the intestine, the probiotics are able to benefit the user. “There are those that improve gastrointestinal transit, others may fight infection, some are related to blood pressure control, and others are anti-allergenic,” she said.

Gigante has just begun a new study

funded by FAPESP to evaluate the maturation and sensory profile of a probiotic

prato sandwich cheese to which

L. acidophilus and

Bifidobacterium have been added.