One of the goals of the study conducted by scientists at the Center for Development of Functional Materials and the Center for Innovation on New Energies is to reduce atmospheric emissions of this greenhouse gas (image: CDMF)

One of the goals of the study conducted by scientists at the Center for Development of Functional Materials and the Center for Innovation on New Energies is to reduce atmospheric emissions of this greenhouse gas.

One of the goals of the study conducted by scientists at the Center for Development of Functional Materials and the Center for Innovation on New Energies is to reduce atmospheric emissions of this greenhouse gas.

One of the goals of the study conducted by scientists at the Center for Development of Functional Materials and the Center for Innovation on New Energies is to reduce atmospheric emissions of this greenhouse gas (image: CDMF)

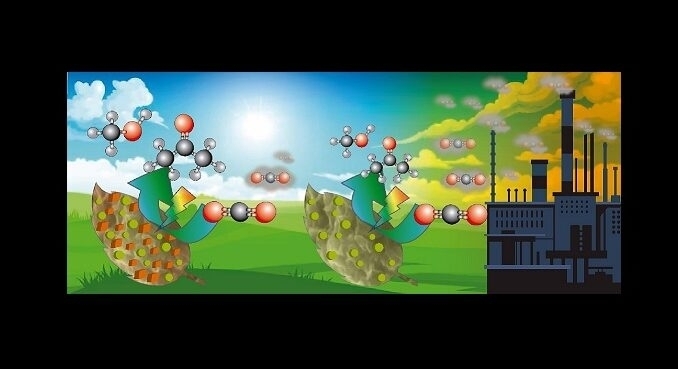

Agência FAPESP* – A study conducted by groups at the Center for Development of Functional Materials (CDMF) and the Center for Innovation on New Energies (CINE) explores methods that promote reuse or conversion of carbon dioxide (CO2) to value-added chemical compounds.

The purpose of the study, reported in an article published in the Journal of Photochemistry & Photobiology A: Chemistry, was to find alternative ways to reduce emissions of this greenhouse gas into the atmosphere by mimicking natural processes such as photosynthesis.

CDMF is one of FAPESP’s Research, Innovation and Dissemination Centers (RIDCs), and is hosted by the Federal University of São Carlos (UFSCar). CINE is an Engineering Research Center (ERC) supported by FAPESP and Shell and jointly hosted by the State University of Campinas (UNICAMP), the University of São Paulo (USP) and the Nuclear and Energy Research Institute (IPEN).

The researchers addressed the challenge by adding small amounts of copper oxide to a semiconductor made of bismuth vanadate (BiVO4) and bismuth oxide (Bi2O3), observing various positive effects with respect to photochemical reduction of CO2. The use of the oxide enhanced charge transfer, mitigated charge recombination, boosted visible light absorption, and increased acetone and methanol yields.

According to Lucia Mascaro, senior author of the article and a researcher at both CDMF and CINE, the method permits substantial CO2 capture as it is produced, by oil rigs, steel mills, hydrogen plants etc. A photocatalyst is used to convert this gas into a different organic molecule, which can be a fuel or another value-added product.

Acetone, for example, is widely used as a solvent in enamel, paint and varnish, edible oil extraction, production of pharmaceuticals and explosives, and as a feedstock in chemical synthesis, among other applications. Methanol is also used as a solvent by the pharmaceutical industry, and as automotive and aviation fuel. Other applications include production of biodiesel and plastic, as well as extraction of animal and plant products.

The article “Contribution of CuO on lamellar BiVO4/Bi2O3-based semiconductor for photoconversion of CO2” is at: www.sciencedirect.com/science/article/abs/pii/S1010603023003660.

* With information from CDMF, a Research, Innovation and Dissemination Center funded by FAPESP

Republish

The Agency FAPESP licenses news via Creative Commons (CC-BY-NC-ND) so that they can be republished free of charge and in a simple way by other digital or printed vehicles. Agência FAPESP must be credited as the source of the content being republished and the name of the reporter (if any) must be attributed. Using the HMTL button below allows compliance with these rules, detailed in Digital Republishing Policy FAPESP.