A class of nanostructured materials studied by Brazilian researchers could be utilized in sectors such as energy, oil and biomedicine

A class of nanostructured materials studied by Brasilian researchers could be utilized in sectors such as energy, oil and biomedicine.

A class of nanostructured materials studied by Brasilian researchers could be utilized in sectors such as energy, oil and biomedicine.

A class of nanostructured materials studied by Brazilian researchers could be utilized in sectors such as energy, oil and biomedicine

By Elton Alisson

Agência FAPESP – Magnesium alloy structured on the nanometer scale (to the billionth of a meter) is capable of safely absorbing and capturing hydrogen, releasing it only when heated. This metal alloy has greater resistance to corrosion and to the wear and tear experienced by conventional metals.

Examples of new materials like these, with applications in areas as diverse as oil, energy and biomedicine, are being developed and characterized by researchers at Universidade Federal de São Carlos (UFSCar).

The possibility of developing this new class of metal alloys, which encompasses amorphous, metastable and nanostructured alloys, was presented during the First São Carlos School of Advanced Studies in Materials Science and Engineering (SanCAS-MSE) held on March 25 – 31 at UFSCar.

Organized under the auspices of the São Paulo School of Advanced Sciences (ESPCA), a FAPESP-funded program, the event was coordinated by professors Edgar Zanotto, Elias Hage Junior and Walter José Botta Filho of the Engineering and Materials Science Department (DEMa) at Universidade Federal de São Carlos.

Through a Thematic Project funded by FAPESP, the DEMa researchers began to develop and characterize metal alloys with better mechanical properties than conventional metals. These new alloys are created in part by the cooling process to which they are submitted.

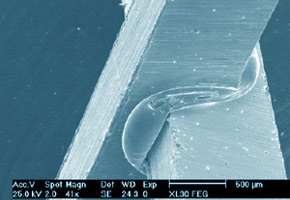

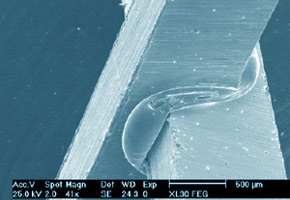

After quickly being cooled in their liquid phase at a rate of 1 million degrees Celsius per second, the atoms that make up the structure of these alloys do not have time to rearrange themselves in an orderly manner and therefore to form the crystalline structures involving small agglomerates of atoms that are normally found in conventional metals. As a result, once solid, these new alloys retain the same disorderly structure of atoms that are present in an amorphous state (such as the liquid state).

Because they are cooled so quickly, the amorphous metal alloys also remain in a state of metastability; that is, they are not in the most stable energy configuration.

In this state, in addition to presenting properties that differ from those of conventional materials, such as greater resistance, when the alloys return to a condition of balance, new microstructures can result, forming, for example, crystalline grains on a nanometer scale.

“This amorphous condition adds very interesting properties to the metal, which are very close to [those of] glass. The metaly become fragile but at the same time have an extremely elevated resistance,” said Botta Filho, coordinator of the project, to Agência FAPESP.

According to Botta Filho, one of the applications of these new nanostructured metal alloys is the solid storage of hydrogen. As part of the project, researchers are developing prototypes for hydrogen storage tanks composed of nanostructured magnesium alloys that are capable of safely confining the gas for later use in energy generation.

Upon being injected into the storage tank, the hydrogen reacts with the magnesium in the alloys that make up the vessel and forms a metallic hydrate. This hydrate then decomposes when heated to a certain temperature, releasing the gas to be burned, for example, in a combustion motor or a fuel cell for power generation.

“This is a very interesting alternative for storing hydrogen that could be utilized to imprison gas as a substitute for high-pressure cylinders, which are very heavy,” says Botta Filho.

Amorphous alloys

Another application of the metal alloys developed and characterized by researchers is recoating the tubes used for oil and gas extraction by the oil industries, which normally present corrosion problems and degrade over time.

In an attempt to solve this problem, several types of coating have been used. Only in recent years, however, have amorphous metal alloys, which have excellent resistance against corrosion and wear and tear, been evaluated for this purpose,” says Botta Filho.

“We developed metal alloys that present greater resistance to corrosion and to wear and tear, and now we are applying them to one of the metal surfaces typically used in tubes,” he says.

The group is also studying the utilization of metal alloys for the development of biodegradable biomedical implants. Made with elements such as calcium, magnesium and zinc, the metal alloys could be used to manufacture screws for bones, for example, which after a certain amount of time would be absorbed by the organism.

“Metal alloys for this purpose are being tested in animal models by scientists in Switzerland, and the performance has been very good,” says Botta Filho.

Researchers are also developing other metal alloys for use in dental implants. Made of nanostructured titanium, the new alloys allow a reduction in the thickness of pins while maintaining the same mechanical resistance. As such, the new pins are less invasive to the patient.

“This type of nanostructured titanium pin is in the approval stages at the U.S. Food and Drug Administration,” says Botta Filho.

During the First São Carlos School of Advanced Studies in Materials Science and Engineering, the UFSCar researchers gave practical classes to postgraduate students and foreign participants on how to develop and characterize amorphous, metastable and nanostructured metals by utilizing equipment available at DEMa.

These activities complemented the theoretical classes given by foreign scientists who are specialists in processing and the properties of advanced metallic materials, scientists such as Gary Purdy, a professor of engineering and materials science at McMaster University in Canada, Lindsay Greer, a professor of materials science at the University of Cambridge in the United Kingdom, and Terence Langdon, a professor at the University of Southern California in the United States.

Republish

The Agency FAPESP licenses news via Creative Commons (CC-BY-NC-ND) so that they can be republished free of charge and in a simple way by other digital or printed vehicles. Agência FAPESP must be credited as the source of the content being republished and the name of the reporter (if any) must be attributed. Using the HMTL button below allows compliance with these rules, detailed in Digital Republishing Policy FAPESP.