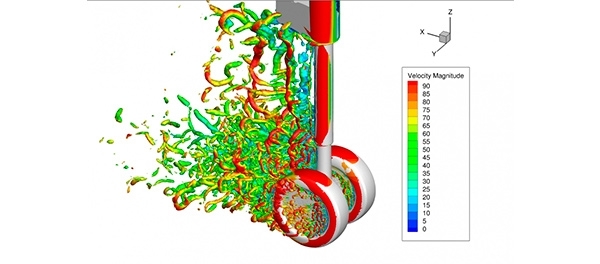

A group at a Brazilian university, partnering with engineers from Boeing, are using computer simulations to identify sources of noise produced by aircraft undercarriages (illustration: simulation of turbulent air flow past landing gear)

A group at a Brazilian university, partnering with engineers from Boeing, are using computer simulations to identify sources of noise produced by aircraft undercarriages.

A group at a Brazilian university, partnering with engineers from Boeing, are using computer simulations to identify sources of noise produced by aircraft undercarriages.

A group at a Brazilian university, partnering with engineers from Boeing, are using computer simulations to identify sources of noise produced by aircraft undercarriages (illustration: simulation of turbulent air flow past landing gear)

By Elton Alisson | Agência FAPESP – Manufacturers of commercial aircraft have been pressured to reduce aircraft noise to mitigate the inconvenience and health problems experienced by people who live near airports.

Aircraft noise is regulated by strict international standards, and companies like Boeing, Airbus, Embraer and Bombardier invest heavily in research and development to make the aircraft they design less noisy.

A study by a group of researchers at the Aeronautical Science Laboratory attached to the University of Campinas’s Mechanical Engineering School (FEM-UNICAMP) in Brazil will help solve at least one of the causes of aircraft noise.

Partnering with Boeing’s engineers in the United States and Brazil, the researchers simulated computationally the turbulent (unsteady or chaotic) air flow around landing gear and succeeded in identifying noise sources that contribute to making this equipment one of the main causes of the noise made by commercial aircraft in or near airports.

The study was conducted under the aegis of a project supported by FAPESP via a Young Investigator Grant and the Center for Research in Mathematical Sciences Applied to Industry (CeMEAI), one of the Research, Innovation and Dissemination Centers (RIDCs) funded by FAPESP.

The results were presented during a session on aeroacoustics held on June 5 in Denver, Colorado (USA), as part of the Aviation Forum hosted by the American Institute of Aeronautics & Astronautics (AIAA).

“We managed to simulate very accurately the physical aspects involved in the turbulence around landing gear and identify some sources of noise,” said William Wolf, a professor at FEM-UNICAMP and principal investigator for the project, in an interview given to Agência FAPESP.

The researchers used parallel computing techniques, in which computers with hundreds of processing cores perform several calculations at the same time, to simulate turbulent air flows in a simplified landing gear model called LAGOON.

Based on the Airbus A320’s undercarriage, LAGOON (LAnding Gear nOise database and CAA validatiON) represents the mechanisms of a real landing gear system and has been studied by several research groups in different countries as part of a project with the same name.

The project was launched in 2006 by Airbus in partnership with ONERA, France’s aerospace research agency, Germany’s Aerospace Center (DLR) and the University of Southampton in the UK, with the aim of appraising techniques of noise simulation in a simplified landing gear system.

To validate their aeroacoustic simulation techniques, the consortium developed and made publicly available a database containing aerodynamic and acoustic data obtained in experiments performed by researchers at ONERA and similar institutions with the simplified landing gear in wind tunnels (facilities in which the effects of real aerodynamic flows past objects can be tested).

“We compared the data from our computer simulations with the measurements made during these experiments with LAGOON in wind tunnels, and the preliminary findings were fairly concordant,” Wolf said. “The computer simulation data succeeded in perfectly reproducing the experimental results.”

To run the computer simulations, the researchers at UNICAMP used software developed by Boeing’s engineers as well as programs they wrote themselves to analyze the aeroacoustic data and perform statistical processing.

Using the statistical processing software to analyze the data from their numerical simulations, they identified turbulent flow structures in the landing gear that are responsible for noise generation.

One of the main sources of landing gear noise was the wheel cavities used for maintenance and brake cooling.

“We found that some of these cavities displayed resonance effects at certain turbulence frequencies, generating intense noise that could be extremely disturbing to the human ear,” Wolf said.

Real landing gear

Wheels and axles are also sources of low- and medium-frequency noise, according to Wolf, as well as the interaction between turbulent flows and these components.

One of the main challenges when simulating landing gear turbulent flows computationally, he explained, is the existence of many equipment details. Hence the idea of using a simplified model like LAGOON to facilitate the simulations.

“This simplified model served as a test to find out whether we could simulate turbulence and identify noise sources in the landing gear,” he said.

The researchers now plan to work on a new project with Boeing to study the 777’s landing gear.

The first author of the study, Túlio Rodarte Ricciardi, a PhD student at UNICAMP supervised by Wolf, is at one of Boeing’s research centers in the US to begin the project.

“The idea of the project is to try to identify noise sources in this realistic landing gear system, which has a larger number of fine details such as brake lines and more complex interactions in turbulent flow than a simplified model,” Wolf said.

The researchers will use the results of the simulations to develop turbulent flow control techniques that reduce the noise produced by the landing gear system.

Republish

The Agency FAPESP licenses news via Creative Commons (CC-BY-NC-ND) so that they can be republished free of charge and in a simple way by other digital or printed vehicles. Agência FAPESP must be credited as the source of the content being republished and the name of the reporter (if any) must be attributed. Using the HMTL button below allows compliance with these rules, detailed in Digital Republishing Policy FAPESP.