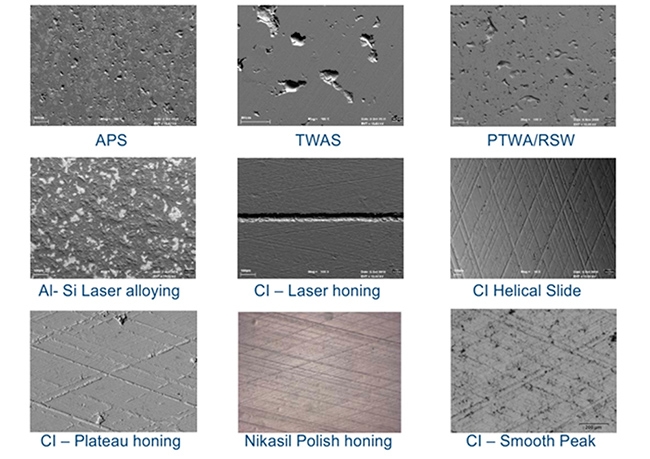

Cylinder bore surface finishes are currently used worldwide. Engines for Brazilian entry-level cars are primarily plateau honed and smooth peaks

Brazilian scientists make outstanding contributions to the prestigious Leeds-Lyon Symposium on Tribology.

Brazilian scientists make outstanding contributions to the prestigious Leeds-Lyon Symposium on Tribology.

Cylinder bore surface finishes are currently used worldwide. Engines for Brazilian entry-level cars are primarily plateau honed and smooth peaks

By José Tadeu Arantes | Agência FAPESP – Optimization of flex-fuel engines has become an urgent technological challenge at a time when fuel ethanol is increasingly being considered an attractive option for reducing emissions of CO2 and other pollutants. In Brazil, almost 90% of all light vehicles licensed in 2014 were flex-fuel vehicles. Albeit less vigorous, the transition from fossil fuels to biofuels is under way in many other countries, mainly via an increase in the proportion of ethanol blended with gasoline.

In this context, the papers delivered by Brazilian researchers at the 2015 Leeds-Lyon Symposium on Tribology (LLST) showed the impacts of the advances in Brazilian research on the use of biofuels in engines. “The Surface Phenomena Laboratory [LFS] at the University of São Paulo’s Engineering School [POLI-USP] is currently one of the sector’s leading research centers,” Tiago Cousseau, one of the LFS-affiliated researchers who attended the symposium, told Agência FAPESP.

Three papers from LFS, one in partnership with Sweden’s Halmstad University and two from the Federal University of Rio Grande do Norte (UFRN), also in Brazil, were delivered at the symposium, one of the oldest and most prestigious conferences in the field. The 2015 edition assembled more than 300 researchers from several countries.

FAPESP supports the research performed at LFS through the project “Tribological challenges in flex-fuel engines”, funded by its Bioenergy Research Program (BIOEN) and Partnership for Technological Innovation Research Program (PITE). The LFS-based tribology project is partnering with Petrobras; automakers Fiat, Renault, and Volkswagen; auto parts manufacturers Mahle and Tupy; the University of Campinas (UNICAMP); the Federal University of the ABC (UFABC); and the University of São Paulo (USP).

“At LFS, we focus above all on reducing engine efficiency losses due to friction and component wear and tear. This has to do with the geometry of parts and also with their microgeometry, defined by the machining operation called honing,” said engineer Amilton Sinatora, Full Professor at POLI-USP and principal investigator of the project.

It is not a matter of mere polishing because in certain regions along the piston excessive polishing can impair the action of lubricant additives. The approach the researchers at LFS take is to control the machining process and observe the part topography at the scale of two-tenths of a micron. “For each region there’s a suitable level of surface roughness in the part finish,” Sinatora said. “You don’t want a perfectly even surface in spatial terms or over time. Early on in the working life of an engine you need more roughness. As the wear and tear increases, the roughness naturally decreases and so does its importance.”

The need to reduce energy consumption has triggered an unstoppable global tendency to produce less viscous lubricants. With less viscosity, engines are more fuel efficient. “But you have to get the right additives for this new generation of lubricants. That’s another area we’re investigating,” Sinatora said.

Another specific feature that must be taken into account in the case of flex-fuel engines; 5% of fuel ethanol is water, which together with the ethanol itself, flushes out the additives deposited on component surfaces by lubricants. “The lubricant additive tribofilm, defined as a thin solid film created by sliding contact, is removed by the ethanol and also by the gasoline consumed in Brazil, which, in compliance with the legislation, can contain up to 27% ethanol, i.e., E27. We work with component geometry and microgeometry and with lubricant formulation, to minimize the drawbacks as much as possible and improve engine performance,” Cousseau said.

Because of the partnership with competing automobile manufacturers, the project “Tribological challenges in flex-fuel engines” cannot produce applicable technology or know-how. The research focuses on understanding the fundamentals (know-why), and each of the partners can then use this knowledge to develop its own processes and products.

Republish

The Agency FAPESP licenses news via Creative Commons (CC-BY-NC-ND) so that they can be republished free of charge and in a simple way by other digital or printed vehicles. Agência FAPESP must be credited as the source of the content being republished and the name of the reporter (if any) must be attributed. Using the HMTL button below allows compliance with these rules, detailed in Digital Republishing Policy FAPESP.