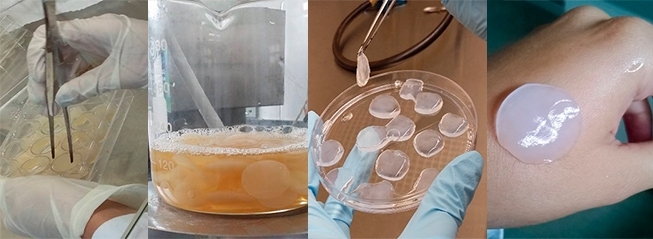

Researchers combine the anti-inflammatory effects of bromelain with bacterial nanocellulose in a product that boosts the healing of wounds, burns and even ulcerations (photos: Angela Faustino Jozala)

Researchers combine the anti-inflammatory effects of bromelain with bacterial nanocellulose in a product that boosts the healing of wounds, burns and even ulcerations.

Researchers combine the anti-inflammatory effects of bromelain with bacterial nanocellulose in a product that boosts the healing of wounds, burns and even ulcerations.

Researchers combine the anti-inflammatory effects of bromelain with bacterial nanocellulose in a product that boosts the healing of wounds, burns and even ulcerations (photos: Angela Faustino Jozala)

By Maria Fernanda Ziegler | Agência FAPESP – When added to bacterial nanocellulose, bromelain – an enzyme extracted from pineapple (Ananas comosus) that exhibits anti-inflammatory and healing effects – can be used in a plaster or gel patch to dress wounds, burns and even ulcerations.

The discovery was made by researchers at the University of Sorocaba (UNISO) and the University of Campinas (UNICAMP) in a study supported by FAPESP. An article describing their findings has been published in Scientific Reports, an online journal owned by Springer Nature.

When bacterial nanocellulose membranes were immersed for 24 hours in a bromelain solution in laboratory tests, their antimicrobial activity increased ninefold.

“Anyone who has ever been severely wounded knows the difference a good dressing makes. It needs to create a barrier against microorganisms in order avoid contamination. It also has to act as an antioxidant in order to mitigate inflammation due to dead cells and pus,” said Angela Faustino Jozala, head of UNISO’s Industrial Microbiology & Fermentation Laboratory and a coauthor of the article.

The researchers found that in addition to enhancing the antimicrobial properties of bacterial nanocellulose, bromelain creates a selective barrier that boosts protein absorption, antioxidant activity and vascularization, all of which contribute to wound healing.

“The main problem when the skin is broken is contamination,” Jozala said. “The patient is susceptible to infection in cases of burns, wounds and ulcerations. Bromelain creates this very important barrier.”

Both bacterial nanocellulose and bromelain are well known both to science and to the pharmaceutical and food industries. Bromelain is used as a meat tenderizer, and its protein breakdown property is much used in pharmaceuticals for the bromelain-based enzymatic debridement of skin cells.

Simply put, bromelain removes necrotic skin from a wound and forms a protective barrier against germs. However, as an enzyme, it has limited use in industry because it is easily denatured and degraded, in addition to being unstable in some formulations.

Bacterial nanocellulose can be used as a temporary substitute for skin or as a dressing for ulcerations, as it relieves pain, protects against bacterial infection, and contributes to tissue regeneration.

Unlike plant cellulose, bacterial nanocellulose is produced pure without other polymers. Moreover, it can be molded into three-dimensional structures capable of retaining a substantial amount of water without gas exchange.

“It’s a biofactory,” Jozala said. “The bacterium Gluconacetobacter xylinus, for example, secretes cellulose as if it were knitting glucose polymers. In our study, we used bromelain to strengthen the healing action of this nanocellulose, which we were already producing via our bioproduct platform.”

Perfect marriage

According to the study, 30 minutes after bacterial nanocellulose membranes were immersed in a bromelain solution, the amount of bromelain released exceeded the amount incorporated. Protein concentration and enzymatic activity also increased. The membranes selectively absorbed low-molecular-weight bromelain components with higher enzymatic activity.

In another important partnership, in addition to that between bromelain and bacterial nanocellulose, the UNISO research team have created a bioproduct production and purification platform with support from FAPESP. This new laboratory is producing bacterial nanocellulose.

Another project also supported by FAPESP and conducted at UNICAMP’s School of Pharmaceutical Sciences is examining bromelain extraction from the pineapple stem and fruit.

“We were already producing bacterial nanocellulose, but we wanted to enhance the product’s healing properties. At a meeting with the UNICAMP group, who had developed a process to extract bromelain from pineapple peel discarded as waste by pulp processors, we realized the combination would be productive,” Jozala said.

The cost of both bromelain and bacterial nanocellulose production and of their purification, was reduced by the decision to use food industry waste such as pineapple peel discarded by fruit pulp processors. The researchers are now seeking more partnerships and aim to find companies interested in large-scale production of the new dressing material.

The article “Bacterial nanocellulose loaded with bromelain: assessment of antimicrobial, antioxidant and physical-chemical properties” (doi: 10.1038/s41598-01718271-4) by Janaína Artem Ataide, Nathália Mendes de Carvalho, Márcia de Araújo Rebelo, Marco Vinícius Chaud, Denise Grotto, Marli Gerenutti, Mahendra Rai, Priscila Gava Mazzola and Angela Faustino Jozala published in Scientific Reports can be read at nature.com/articles/s41598-017-18271-4.

Republish

The Agency FAPESP licenses news via Creative Commons (CC-BY-NC-ND) so that they can be republished free of charge and in a simple way by other digital or printed vehicles. Agência FAPESP must be credited as the source of the content being republished and the name of the reporter (if any) must be attributed. Using the HMTL button below allows compliance with these rules, detailed in Digital Republishing Policy FAPESP.