In a workshop at FAPESP, a USP researcher affirms that new scientific advances allow second-generation ethanol production, but enzyme studies must be intensified to make this more affordable (CTBE)

New scientific advances have made cellulosic ethanol production a reality, but more focused research is needed to make it economically viable on an industrial scale.

New scientific advances have made cellulosic ethanol production a reality, but more focused research is needed to make it economically viable on an industrial scale.

In a workshop at FAPESP, a USP researcher affirms that new scientific advances allow second-generation ethanol production, but enzyme studies must be intensified to make this more affordable (CTBE)

By Fábio de Castro

Agência FAPESP – New scientific advances have made cellulosic ethanol production a reality, but more focused research is needed to make it economically viable on an industrial scale.

The shortest path to achieving this goal is to intensify studies to perfect the enzyme cocktails that are used to degrade the cell walls of sugarcane, says professor Igor Polikarpov from the Universidade de São Paulo (USP) São Carlos Institute of Physics (IFSC).

One of Brazil’s foremost specialists in enzyme crystallization, Polikarpov gave a lecture entitled “Biological approach to the degradation of complex polysaccharides” in São Paulo on Monday, May 14th, during the workshop held by the Centro Paulista de Pesquisa em Bioenergia, Nottingham University and the University of Birmingham.

Sponsored by the FAPESP Bioenergy Research Program (BIOEN), the event sought to present the results of bioenergy research underway at USP, the Universidade Estadual de Campinas (Unicamp) and the Universidade Estadual Paulista (Unesp), as well as at Nottingham University and the University of Birmingham—both in the United Kingdom—with the aim of discussing collaborative research and planning future projects together.

The international scientific community has been looking for industrial-scale production technology for cellulosic ethanol: that is, ethanol derived from sugarcane cellulose. Today, ethanol can only be made from saccharose, which makes up one third of the plant’s biomass. Cellulosic ethanol would make it possible to use the other two thirds, thereby increasing productivity without increasing the planted area.

The Danish biotechnology company Novozymes announced in April that it had developed an enzyme that, using current hydrolysis technology, could be used to produce cellulosic ethanol at prices competitive with the ethanol produced in Europe. The process, however, is still very expensive in relation to ethanol production costs in Brazil.

This scientific advance accentuates the importance of the enzymatic route to ethanol production, says Polikarpov. “It is great news because it means that if we improve this process even further, we will arrive at a second-generation ethanol that is viable on an industrial scale. In order to do this, we have to invest in studying enzymes, which are the factors that most increase the cost of making cellulosic ethanol,” he said to Agência FAPESP.

According to Polikarpov, studies show that when the enzymatic load is reduced by half, the final cost of ethanol falls by 20%. “Enzymes weigh in more heavily than electric power, for example, in the cost of industrial production. We have to intensify our research on components that could act synergetically with the enzyme cocktails on the market today. That way, we will be able to make cellulosic ethanol even more efficient and less expensive,” he affirmed.

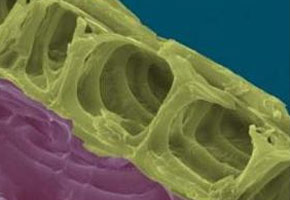

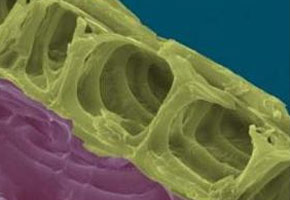

The three main components of sugarcane biomass are cellulose, hemicellulose and lignin. The first two are fundamentally composed of sugar, but their molecules form crystalline fibers that make the job of separating glucose molecules for fermentation and ethanol production difficult.

“Throughout evolution, plants developed cell wall structures that protected them from degradation by microorganisms. Aside from being crystalline, cellulose is covered with hemicellulose and lignin, making it impermeable to enzymes,” explained Polikarpov.

“Usually, physical and chemical processes are used to loosen this structure to allow the enzymes to attack the cellulose and generate simple sugars that will be fermented for the production of ethanol,” he said.

The use of enzymes is an interesting strategy, according to Polikarpov, because enzymes are quite efficient and generate few undesirable by-products. There isn’t, however, any one enzyme that does the job alone.

“Sugarcane biomass has a very complex morphology and composition, and these complexities should be attacked with complex mixtures of enzymes. Each enzyme will cleave a specific connection. A combination of enzymes must be found that will together attack this type of biomass and dissolve it,” said Polikarpov.

Molecular composition

The optimized enzyme cocktail for each type of biomass will be different, according to Polikarpov. “Not only will we need a different cocktail for each different type of biomass, but we will also need different cocktails conceived for each specific form of pretreatment given to the same biomass because the morphology and composition in each case is different,” he said.

In addition to studying the composition of enzyme cocktails that work on biomass, Poikarpov’s group studies the pretreatment of sugarcane substrates. “We decided to study the molecular composition of biomass in depth because it is the substrate for the enzymes throughout the pretreatment processes,” he said.

His group has already shown which commercial mixtures of enzymes aren’t always optimal for the hydrolysis of pretreated sugarcane bagasse. These processes could become much more efficient if it were possible to add other enzymes to the enzyme preparations on the market.

“On the one hand, we tried to understand the molecular structure of the substrate—the biomass—and on the other hand, to understand how the enzymes interact with the substrate. We want to discover new enzymes that could be added to enzyme cocktails so as to increase their efficiency. We have shown that we can already do that,” he noted.

Polikarpov coordinates two Thematic Projects within the BIOEN Program: “Structure and function of enzymes and auxiliary proteins from Trichoderma, active in cell-wall hydrolysis” and CeProBIO, the Center for Biological and Industrial Processes for Biofuels.

He also coordinates “Target analysis of microbial lignocellulytic secretomes—a new approach to enzyme discovery” and “EMU: Facility for advanced studies of nanostructured materials and biosystems”, both funded by FAPESP, within its Regular Research Support and Multiuser Equipment Programs, respectively.

Republish

The Agency FAPESP licenses news via Creative Commons (CC-BY-NC-ND) so that they can be republished free of charge and in a simple way by other digital or printed vehicles. Agência FAPESP must be credited as the source of the content being republished and the name of the reporter (if any) must be attributed. Using the HMTL button below allows compliance with these rules, detailed in Digital Republishing Policy FAPESP.