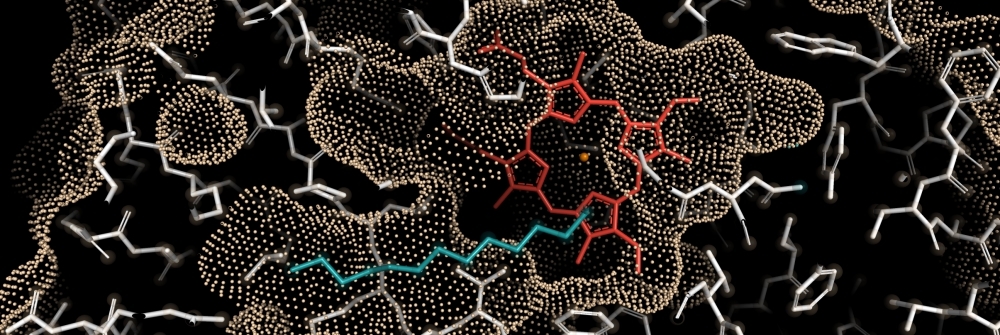

A biocatalyst discovered by Brazilian researchers has the potential to increase renewable biofuel output by removing obstacles in technology and production processes, as well as enhancing the manufacturing of bioplastics and biopolymers (image: researcher’s archive)

A biocatalyst discovered by Brazilian researchers has the potential to increase renewable biofuel output by removing obstacles in technology and production processes, as well as enhancing the manufacturing of bioplastics and biopolymers.

A biocatalyst discovered by Brazilian researchers has the potential to increase renewable biofuel output by removing obstacles in technology and production processes, as well as enhancing the manufacturing of bioplastics and biopolymers.

A biocatalyst discovered by Brazilian researchers has the potential to increase renewable biofuel output by removing obstacles in technology and production processes, as well as enhancing the manufacturing of bioplastics and biopolymers (image: researcher’s archive)

By Mônica Tarantino | Agência FAPESP – In recent decades, scientists have sought solutions to improve the sustainable production of biofuels from renewable sources. The latest advance in this field was announced at the end of May by Brazilian researchers and could boost the production of sustainable biofuels for aviation and maritime shipping.

“After three and a half years of research, we identified an enzyme that can replace the traditional catalysts used in thermochemical routes for the production of aviation biokerosene,” said Letícia Zanphorlin, principal investigator for the project and head of the Brazilian Biorenewables National Laboratory (LNBR) at the Brazilian National Center for Research in Energy and Materials (CNPEM).

The enzyme discovered by the CNPEM group is OleTPRN, a polyunsaturated alkene-producing decarboxylase belonging to the cytochrome P450 superfamily. This metalloenzyme derived from the bacterium Rothia nasimurium promises to be the key to development of novel biotechnological routes in the production of renewable hydrocarbons for aviation from different feedstocks, such as oleaginous biomass from soy, macaw palm (Acrocomia aculeata) or corn, among others, and lignocellulosic biomass from sugarcane bagasse or straw and in the paper industry.

“Compared with conventional or chemical catalysts, the novel enzyme decarboxylates fatty acids [breaking the carbon-carbon bond and removing the carboxyl group] with high yields and is selective for different sizes and types of carbon chain. It promotes deoxygenation, which is one of the trickiest processes to master in producing SAF [sustainable aviation fuel],” Zanphorlin explained.

Oxygen can damage aircraft parts and engines, she added, which helps understand why biofuels already mass-produced in Brazil, such as ethanol and biodiesel, are not used in aviation and explains the demand for novel biocatalysts. In general, conventional catalysts used in aviation fuel production involve metals such as cobalt, platinum, nickel or palladium.

“To produce the deoxygenation reaction, these metallic catalysts must be applied under severe conditions, particularly high temperature and pressure, and can be environmentally harmful, producing technological waste and leading to financial losses,” she said.

An article on the research is published in Proceedings of the National Academy of Sciences (PNAS).

The research was supported by FAPESP via four projects (18/04897-9, 19/08855-1, 19/12599-0 and 20/01967-6).

According to the researchers, enzymes act as biological catalysts, accelerating chemical reactions in the living organisms present in nature. In the study in question, the enzyme converted fatty acids in a single step into alkenes (olefins), a type of hydrocarbon and an important chemical intermediary.

Fatty acids are essential components of lipids, a class of organic compound that includes all kinds of fat and oil. Lipids are found in plants, animals and microorganisms.

The discovery and elucidation of the molecular mechanisms involved in the enzyme’s action were the fruit of a multidisciplinary approach. The scientists searched public databases for enzymes with specific properties and functions, using bioinformatics tools and genomic data for microorganisms. Candidate enzymes were analyzed at the atomic level using synchrotron light, a type of high-flux high-brightness electromagnetic radiation encompassing a large proportion of the spectrum, from infrared through ultraviolet to X-rays. Synchrotron light is produced when a beam of charged particles accelerated almost to the speed of light is deflected by a magnetic field. When applied to protein crystals, it causes electron diffraction and permits elucidation of their three-dimensional structure.

“We evaluated the position of every amino acid in the enzyme’s atomic structure, and mapped its intermolecular interactions with fatty acids,” Zanphorlin said, noting that this showed them all the possible applications of the discovery.

In parallel with this laboratory investigation, other teams at CNPEM worked on patent filings and on technical, economic and environmental analysis of the biological routes, the results of which will be published soon.

“A patent on the enzyme was applied for in 2021. One of CNPEM’s key advantages is that we can develop a technological solution, implement a pilot project, ramp it up to an industrial scale, and perform the technical, economic and environmental assessments needed to detect any potential improvements in the innovation as it’s being developed,” Zanphorlin said.

There are exciting possibilities for the production of aviation biofuels using the enzyme. “Brazil currently produces some 150 million metric tons of lignocellulosic waste from sugarcane in dry mass terms. This could be increased without adverse environmental impacts,” she said.

To implement the technology, biofuel production facilities would need to be adapted, but the distribution infrastructure used by fossil fuels could be shared by renewables acting as “drop-in” fuels – substitutes for petroleum-derived hydrocarbons that would not require adaptation of engines, fuel systems or distribution networks.

The researchers are optimistic about applications in several industrial sectors. “The versatility of this enzyme makes it adaptable for use in different sectors. Alkenes are produced by enzyme reaction and are the basis for some two-thirds of the products made by the chemical industry today, especially polymers and plastics. They’re also essential to the food, cosmetics, pharmaceutical and transportation sectors,” Zanphorlin said.

The article “Dimer-assisted mechanism of (un)saturated fatty acid decarboxylation for alkene production” is at: www.pnas.org/doi/10.1073/pnas.2221483120.

Republish

The Agency FAPESP licenses news via Creative Commons (CC-BY-NC-ND) so that they can be republished free of charge and in a simple way by other digital or printed vehicles. Agência FAPESP must be credited as the source of the content being republished and the name of the reporter (if any) must be attributed. Using the HMTL button below allows compliance with these rules, detailed in Digital Republishing Policy FAPESP.