Developed by a FAPESP-funded company, the instrument makes it easier for visually impaired people to read and write

Developed by a FAPESP-funded company, the instrument makes it easier for visually impaired people to read and write.

Developed by a FAPESP-funded company, the instrument makes it easier for visually impaired people to read and write.

Developed by a FAPESP-funded company, the instrument makes it easier for visually impaired people to read and write

By Elton Alisson

Agência FAPESP – Tece, a company founded by a biologist with a master’s in Education who is currently a doctoral student at Universidade Estadual Paulista (UNESP), has developed a new version of a manual writing instrument for visually impaired people – called a positive slate– that reduces the time required to learn the Braille reading and writing system.

Funded by FAPESP’s Program for Innovative Research in Small Companies (PIPE), the company has begun commercialization of the product in Brazil and has plans to export it. “In total, the process of product development and testing at institutions that serve people with visual impairment took six years,” explains Aline Picolli Otalara, founder of the company.

According to the researchers, the conventional slate has existed since 1937 when the Frenchmen, Louis Braille (1809-1852), presented the first version of the instrument, composed of two metal or plastic boards the size of small school rulers mounted on top of each other by a hinge on the left side and with space that allows the insertion of a sheet of paper.

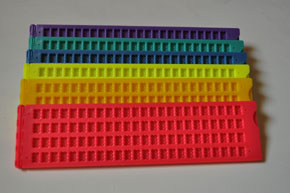

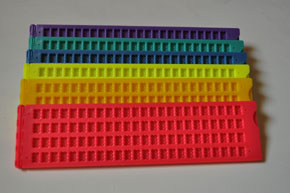

The top slate has several hollow rectangles that correspond to the spaces of written Braille (known as Braille cells). The Braille cells on the lower slate each have six concave points (in low relief).

When introducing an instrument (known as a stylus) with a concave point into each hollow rectangle on the top slate, pressure is applied to the sheet of paper wedged between the two slates and against the concave points found on the lower slate to form a Braille symbol corresponding to the letters, numbers or any other character that the user desires to write. With the sheet turned in the opposite direction, visually impaired people can identify the relief points, manually reading the words written by puncturing the paper.

One of the main problems associated with the conventional device, however, is that because the points are written in low relief and reading is in high relief, writing begins from right to left and characters must be written backwards (as if in a mirror). As a result, when the sheet is turned over to be read (from left to right), the characters are on the correct side.

Moreover, in the Braille system, several letters are inverted forms of other letters. “This demands greater efforts on the part of anyone who is learning the Braille system because he has to learn one alphabet to read and another to write,” affirmed Otalara.

To resolve the problem, in 2007, through a PIPE-funded project, the company developed a slate that is aesthetically similar to the conventional instrument but allows users to write in high relief. For this reason, unlike the conventional instrument, the top slate has six points in each Braille cell in a convex form (high relief). To puncture them, Tece developed a stylus that is similar to a pen with a tip with a closed concavity, which forms high-relief points when pressure is applied on the paper between the two slates.

In this manner, the user can begin to write from left to right because the paper no longer needs to be turned over to be read. Furthermore, users need only learn one alphabet to read and write in Braille. “Throughout the project, we developed several prototypes of the product to evaluate any technical problems caused by this inversion of written Braille,” said Otalara.

One of these technical problems, according to researcher, is that the six points in each of the Braille cells are very close to one another. In marking a convex dot with the stylus with a closed cavity to make a Braille symbol in high relief, there was a “ghost” dot that made it difficult for the visually impaired to read.

In the first stage of the project, the company’s researchers created several different prototypes with different distances between the points, and conducted a series of reading tests with texts written using the new instrument. “The emergence of these ‘ghost’ dots was a factor that had until now impeded the development of this material,” explained Otalara. “All our previous attempts to develop a slate that wrote in high relief failed because we could not get pass this stage,” she added.

Through another PIPE-funded project, the company conducted a Braille system course to evaluate the time participants needed to learn Braille using the slate Tece developed.

The course was conducted with students pursuing teaching licenses at UNESP in Rio Claro because, according to Otalara, it was hard to find visually impaired students that had not yet had contact with a common slate. Even so, the teaching students represented the majority of users of this type of material. “There is a much greater number of teachers learning the Braille system than there are, in fact, blind users,” noted the researchers.

The researchers found that with the slate that they developed, the learning period could be reduced by 60% for future educators. With this, according to Otalara, it is possible to reduce the investment in teacher training, which will facilitate the learning process and increase public interest, in general, in learning the Braille system.

“There is a very negative impression about the Braille system. People already imagine that it is difficult to learn, and when they saw that they had to learn to write backwards, the stigma, particularly among teachers and children, increased even more,” said Otalara.

Tece named the product “positive slate” because when teaching Braille, the low-relief dots, which do not appear when writing, are called negative points. The high-relief points – which are legible and can be read manually when the sheet is turned over – are called positive points.

Braille writing machines

The company will use some of the results of positive slate projects to develop, also with PIPE’s support, a Braille-writing machine. Widely used by visually impaired people both in classrooms and the workplace, the equipment is relatively expensive – it costs R$ 2,000 – and as they are not manufactured in Brazil, the price has remained practically the same since they were created.

The Brazilian company intends to develop a national version of the product, make it economically feasible and improve some technical aspects, like weight and design, to make it easier for the user to handle and transport. To develop the prototype, the company formed a partnership with the Renato Archer Information Technology Center (CTI) in Campinas, which has a prototyping center and assistive technology laboratory.

The six keys corresponding to Braille dots and the material printed by the equipment will follow the standards of the positive slate developed by the company. Although it is a little larger than the standard used in low-relief Braille (negative), the new standard will facilitate tactile reading. “As the dots are a little ‘fatter,’ they are more similar to the Braille printed in books,” noted Otalara. “That’s why they are easier to read tactilely,” she acknowledged.

The development of the positive slate resulted in a patent request that is currently in the evaluation stages. The product is sold on the company’s site – which has access tools for the visually impaired – and in specialized stores.

Republish

The Agency FAPESP licenses news via Creative Commons (CC-BY-NC-ND) so that they can be republished free of charge and in a simple way by other digital or printed vehicles. Agência FAPESP must be credited as the source of the content being republished and the name of the reporter (if any) must be attributed. Using the HMTL button below allows compliance with these rules, detailed in Digital Republishing Policy FAPESP.