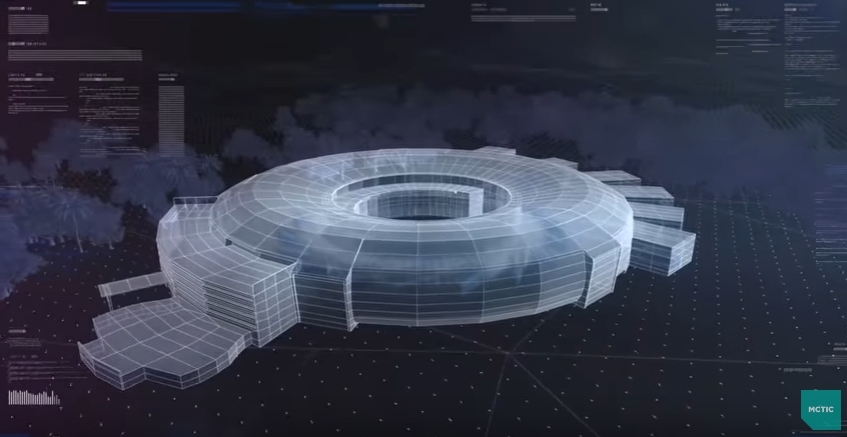

Program supports projects that will upskill suppliers to Brazil's new synchrotron light source (image: MCTI)

Program supports projects that will upskill suppliers to Brazil's new synchrotron light source.

Program supports projects that will upskill suppliers to Brazil's new synchrotron light source.

Program supports projects that will upskill suppliers to Brazil's new synchrotron light source (image: MCTI)

By Claudia Izique | Agência FAPESP – Ten companies have been selected in the second call for proposals to develop products and services for Sirius, Brazil’s new synchrotron light source, which is under construction at the National Synchrotron Light Laboratory (LNLS) in Campinas, São Paulo State.

Each of the selected companies has up to 250 employees and has been operating for at least two years. They will be supported by the PIPE/PAPPE Grant Program, which is jointly funded by FAPESP and FINEP, the Brazilian Innovation Agency, and have two years to respond to the technological challenges (PDF in Portuguese) of building and operating a fourth-generation research facility that is competitive with synchrotrons that are under construction or have been recently completed worldwide.

These challenges are far from trivial for the companies concerned. Sirius will comprise a set of electron accelerators and experimental stations, called beamlines, installed in a 68,000 square meter building, itself a challenge for Brazilian engineering because of the formidable thermal and mechanical stability specifications involved.

The storage ring, with a diameter of 518.4 meters and a beam energy of 3 GeV (gigaelectronvolts), will provide space for up to 40 workstations, where researchers will use synchrotron light to analyze the structure of materials at the atomic level. Their findings will open up new opportunities for research and development in strategic areas such as biotechnology, nanotechnology, energy and environmental management, among many others.

The companies selected in the PIPE/PAPPE call aim to qualify as suppliers of technological solutions for Sirius, including unmanned vehicles for monitoring the concrete tunnel that will house the accelerators, ultra-high-vacuum (UHV) chambers, and additive manufacturing processes.

“After two years, all these companies are expected to deliver prototypes for testing by the team of engineers and scientists responsible for the overall design of Sirius,” said LNLS Director José Roque da Silva.

Creating a local supplier base

Eight other companies, selected in 2015 in the PIPE/PAPPE Grant Program’s first call for proposals, are already developing 13 projects for Sirius, including photon blockers, X-ray detectors, and covalent ceramics.

“The idea is to create a local supplier base and enable the companies concerned to use the knowledge they acquire in this project elsewhere in Brazil and the world,” Roque da Silva said.

For example, FCA Brasil, a Campinas-based manufacturer of special metal parts and equipment, was selected in the first call to make stainless steel booster vacuum chambers for Sirius and in the second call to make aluminum vacuum chambers.

A synchrotron source’s UHV chambers delimit the environment traversed by the electron beam and keep the pressure below 1 nTorr (<10-7 Pa), or a trillionth of atmospheric pressure, and must therefore be fabricated with special materials and dimensions.

FCA has already mastered the technology for producing conventional booster chambers in stainless steel. The challenge now is to make them in aluminum. “The advantages of aluminum are that it’s light and permeable, thereby improving vacuum quality,” said Artur Domingues Tavares da Silva, who is responsible for the project approved in the second call. The welding of the parts is the main problem. “There must be no porosity, and the aluminum has to be made compatible with other materials used in the flanges, such as stainless steel or copper.”

Founded in 2005 and currently staffed by eight professionals, FCA supplies conventional chambers for UVX, the second-generation synchrotron now operating at the LNLS. The expertise acquired there has enabled the company to expand its customer base in Brazil. “IPEN, the Energy & Nuclear Research Institute, is a customer, along with several other federal research labs,” said Daniela Munerato Arroyo, one of FCA’s partners.

The Brazilian Vacuum Society (SBV) recently recognized FCA as “the only company in Brazil known to be capable of fabricating vacuum components and equipment in the UHV range or below”. The company is starting to internationalize. “We’re in touch with CLS, the Canadian Light Source, and talking to the Giant Magellan Telescope in Chile,” Arroyo said.

Healthy competition

FCA is not the only company selected to supply UHV chambers. “Competition between companies is healthy,” Roque da Silva said. Promac Equipamentos, based in Sumaré, São Paulo State, will also develop prototype booster chambers. “We have 150 employees, we’ve been operating in this segment for 30 years, and our annual sales currently run to R$18 million,” said Diego Roberto Dias da Cruz, the engineer responsible for the project. Promac specializes in material handling and transportation. Its customer portfolio includes Gerdau, Votorantim and ArcelorMittal. “We’re looking for new challenges. This will require a great deal of R&D and highly qualified staff,” Cruz said.

Other challenges, such as the development of unmanned vehicles for monitoring the storage ring tunnel, aroused strong interest from bidders, but only one company was selected. “We were chosen to design a battery-powered vehicle on rails with an on-board computer, camera, communications and anti-collision system, among others. The main challenge is image recognition,” said Nilton Dias Borrego, technical director of Wisersoft Tecnologia em Sistemas (read more in Portuguese at agencia.fapesp.br/22213).

Founded in 2008 for the development of automation systems, and with customers in the aerospace industry, Wisersoft sees the Sirius challenge as an opportunity to expand into new markets. “The same technology can be used to inspect tunnels in metro systems as well as in mine galleries and even at ports,” Borrego said. “The vehicle is operated by remote control, so it can also be used in large warehouses, mills or factories.”

Roque da Silva’s team of engineers and scientists at the LNLS will oversee all of the projects. “Some of the suppliers selected in the first call have made considerable progress with projects such as detectors, ceramics, and some of the electronics,” he said. FCA is ready to compete in the global marketplace, in his view. “Sirius and FAPESP have transformed a family business into a world-class high-tech company.”

According to Roque da Silva, there will also be ample international opportunities from the technological standpoint for the companies that are developing radiation-shielded experimental hutches. “The LNLS itself opens doors internationally,” he said. “Our meetings and seminars bring together synchrotron specialists from all over the world.” Nevertheless, he stresses, “these companies will need support to penetrate international markets, especially funding and assistance to surmount legal and logistical hurdles.”

For more information about Sirius, visit lnls.cnpem.br/sirius-en and (in Portuguese) youtube.com/watch?v=Q6YFNPkTWiM.

Republish

The Agency FAPESP licenses news via Creative Commons (CC-BY-NC-ND) so that they can be republished free of charge and in a simple way by other digital or printed vehicles. Agência FAPESP must be credited as the source of the content being republished and the name of the reporter (if any) must be attributed. Using the HMTL button below allows compliance with these rules, detailed in Digital Republishing Policy FAPESP.