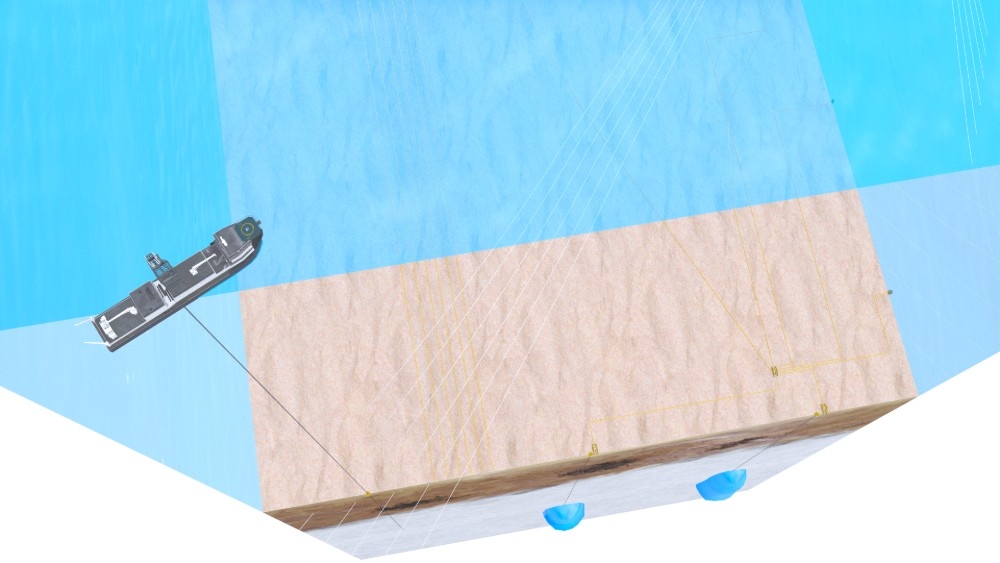

The Research Center for Gas Innovation is developing technology to separate CO2 and methane in oil and gas exploration and store it in offshore salt caverns (image: RCGI)

The Research Center for Gas Innovation is developing technology to separate CO2 and methane in oil and gas exploration and store it in offshore salt caverns.

The Research Center for Gas Innovation is developing technology to separate CO2 and methane in oil and gas exploration and store it in offshore salt caverns.

The Research Center for Gas Innovation is developing technology to separate CO2 and methane in oil and gas exploration and store it in offshore salt caverns (image: RCGI)

By André Julião, in London | Agência FAPESP – A set of technologies that is expected to have its first results four years from now is designed to resolve one of the world’s greatest oil and gas exploration challenges today: carbon dioxide (CO2) and methane (CH4) emission in the atmosphere.

The innovation, the result of a patent deposited in 2018, consists of injecting the CO2 and CH4 that comes from wells during oil extraction into salt caverns as a way to reduce the amount of carbon gas in the emissions.

The first “pilot cavern” may be ready by 2022 and is the result of studies carried out at the Research Center for Gas Innovation (RCGI), established by FAPESP and Shell, headquartered at the Polytechnic School of the University of São Paulo (Poli-USP). The RCGI is one of the Engineering Research Centers (ERC) funded by FAPESP in partnership with companies.

“This is a concept known as Carbon Capture Storage (CCS). In this case, the CO2 is stored in large caverns in the salt layer itself. This is perhaps one of the best ways to obtain clean energy from a fossil fuel during the production process,” said Julio Meneghini, a professor at Poli-USP and RCGI coordinator.

Meneghini was one of the speakers on the first day of sessions held during FAPESP Week London, taking place in London February 11-12, 2019.

The site of the cavern in which the initial tests will be run has not yet been determined, but is expected to be in one of the areas that hold pre-salt oil fields. During this initial phase, it will likely be half the size of the caverns that will be used when the technology is operating at full capacity: 450 meters in height by 150 meters in width.

According to Meneghini, Brazil will be the first place in the world to use this concept, and the model could be exported to other countries. In addition to storing CO2, the cavern can also store methane and separate the two gases using gravity. Since CH4, also referred to as natural gas, has a lower density, it will remain in the top part of the cavern for possible later use. The carbon dioxide will remain in the lower part. The researcher expects that at least the initial cavern construction tests will take place by 2022. The most optimistic scenario provides that 2022 will be the year the cavern begins operations.

Carbon gas capture

“What is new is not just the cavern, but the various innovations that go along with it, such as supersonic gas separators, compressors designed optimizing topology, and graphene nanotube membranes used to separate the gases,” said the researcher.

The new CO2 compressors are vital to the functioning of the project, given the extreme pressure conditions found there. From the water line itself, the distance from the surface to the sea floor is 2,000 to 3,000 meters in depth. That and other variables leave gas in what is known as the supercritical state.

“It has the density of a liquid and the viscosity of a gas. Therefore, a compressor designed for that specific condition is necessary. We have developed a new methodology that consists of optimizing the compressor precisely to the conditions of the supercritical fluid,” Meneghini told Agência FAPESP.

Another technology related to the carbon dioxide caverns are the gas separators. Also because of the pre-salt conditions, what is known as variable geometry supersonic separators are being developed for each composition of the mixture of CO2 and methane.

Besides that, graphene nanotube membranes are also being developed to separate the gases with the least possible energy loss.

Carbon gas capture can also occur during ethanol generation. “The captured gas may be stored or used in the food industry, in the production of carbonated drinks like soda. By doing this, negative emission values can be obtained,” said Meneghini, who explained that the experiments are still being carried out on a small scale.

The technologies are emerging within a context of increasing per capita energy demand throughout the world and the need to mitigate emissions in light of global climate change.

Read more about FAPESP Week London at: www.fapesp.br/week2019/london/.

Republish

The Agency FAPESP licenses news via Creative Commons (CC-BY-NC-ND) so that they can be republished free of charge and in a simple way by other digital or printed vehicles. Agência FAPESP must be credited as the source of the content being republished and the name of the reporter (if any) must be attributed. Using the HMTL button below allows compliance with these rules, detailed in Digital Republishing Policy FAPESP.