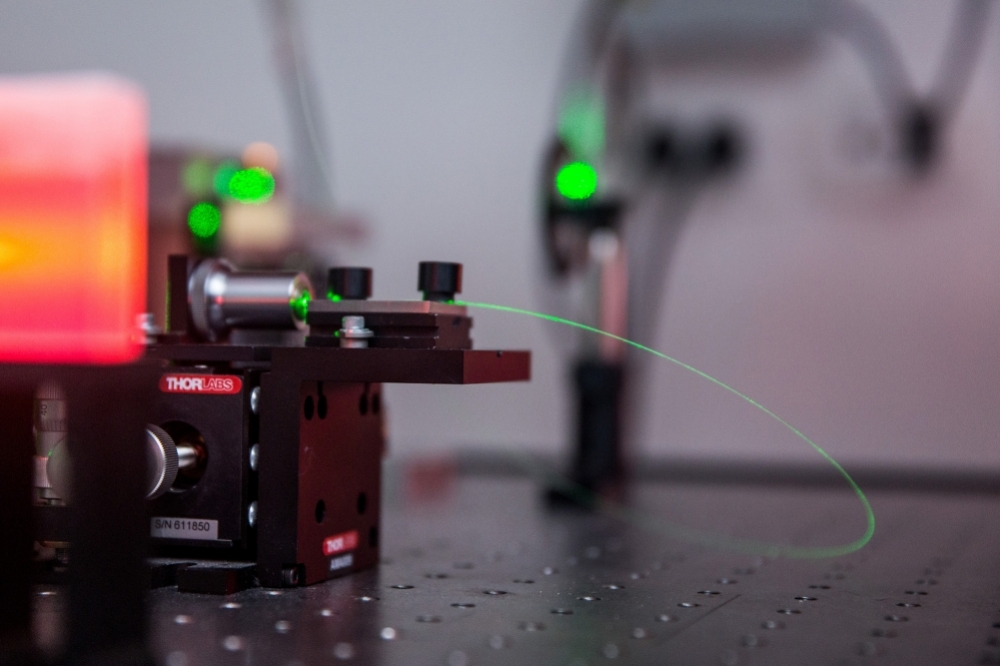

Research center unveiled in São Paulo aims to help surmount challenges of mass production to achieve high quality standards required for industrial applications (photo: Leandro Negro/Agência FAPESP)

Research center unveiled in São Paulo aims to help surmount challenges of mass production to achieve high quality standards required for industrial applications.

Research center unveiled in São Paulo aims to help surmount challenges of mass production to achieve high quality standards required for industrial applications.

Research center unveiled in São Paulo aims to help surmount challenges of mass production to achieve high quality standards required for industrial applications (photo: Leandro Negro/Agência FAPESP)

By Elton Alisson | Agência FAPESP – Twelve years after the discovery of graphene, several countries are still in a race to mass-produce this material, which is obtained from graphite, at a high standard of quality. Graphene is thin, light, tough, impermeable and flexible. These and other properties make it ideal for use in smartphones, tablets and high-definition TVs, among other applications.

Brazil’s participation in the race was bolstered on March 2 by the unveiling of the Advanced Graphene, Nanomaterials & Nanotechnology Research Center (MackGraphe) at Mackenzie Presbyterian University (UPM) in São Paulo.

Built with support from FAPESP, the Mackenzie Presbyterian Institute and the National Council for Scientific & Technological Development (CNPq), MackGraphe has received an investment of more than R$100 million and is the first center of its kind in Latin America.

“FAPESP will invest R$20 million in MackGraphe,” said FAPESP President José Goldemberg at the unveiling ceremony. “It may invest more, depending on the scientific research proposals submitted to us by researchers there.”

FAPESP Vice President Eduardo Moacyr Krieger and Chief Executive Officer José Arana Varela also attended the ceremony.

MackGraphe has nine stories and more than 4,000 square meters of floor area. Its remit includes exploring the properties of graphene and other two-dimensional (2D) materials with a view toward industrial applications. 2D materials are a class of nanomaterials whose total thicknesses range from an atomic layer to tens of nanometers.

MackGraphe’s state-of-the-art laboratories and equipment are staffed by a team of 15 researchers, of four nationalities, who specialize in producing and characterizing graphene for industrial applications.

“Our research will be based on an applied engineering vision, so close interaction with the productive sector will be essential,” Eunézio Antônio Thoroh de Souza, Coordinator of MackGraphe, told Agência FAPESP.

MackGraphe’s interaction with industry will initially focus on photonics, energy and composites (combinations of materials, such as graphene with a polymer). A significant number of companies are operating in these areas in Brazil.

Representatives of the center say it will then extend its interaction to other sectors, such as agriculture, in which Brazil is a leading exporter.

“We don’t want to confine our research to photonics, energy and composites. We plan to talk to firms in other sectors, such as agribusiness, with a view to making MackGraphe self-sustainable,” said Maurício Melo de Meneses, President of Mackenzie Presbyterian Institute, which owns UPM.

Window of opportunity

In addition to financial sustainability, interaction with industry will also aim at mastery of the graphene-production process and development of graphene-based innovations within five years, the estimated R&D window of opportunity in this case.

According to researchers in the field, Brazil is strongly positioned to make good use of this window because it is one of the world’s leading graphite producers. A kilogram of graphite, which costs a dollar, produces 150 g of graphene, which currently has a market value of US$15,000.

Furthermore, as of yet, there is no global graphene manufacturing chain. The world has a silicon-production chain, but such a system for graphene is only in the early stages of planning.

“Graphene presents Brazil with an excellent opportunity precisely because it’s just starting to take off,” said Antônio Hélio de Castro Neto, a Brazilian physicist who heads the National University of Singapore’s Center for Advanced 2D Materials and Graphene Research Center, which collaborates with MackGraphe. “If we wait too long, we’ll be left out of the race and other countries will develop technologies based on graphene. We’ll have to pay royalties to use them, and we’ll miss the opportunity to share in the wealth graphene will create.”

Quality assurance

According to Castro, lead investigator for the project supported by FAPESP that gave rise to MackGraphe, quality assurance is one of the main challenges facing industrial applications of graphene today.

Graphene is currently made via different production routes by hundreds of firms in the EU, US and China, among other countries. Its quality varies enormously, and there are no specifications for industrial applications, Castro noted.

“This makes industrial use of graphene difficult because if a manufacturer buys low-quality material the application just won’t work,” he said.

According to Castro, research is under way worldwide on more than 2,000 2D materials with different physicochemical properties, although the focus is currently on graphene.

The research center he heads in Singapore, for example, has applied for more than 100 patents in the past four years, with 40% relating to graphene-production processes.

The number of Brazilian scientific articles on nanotechnology and nanomaterials including graphene rose by 700% between 2005 and 2015 compared with the previous decade, according to the Ministry of Education’s Office for Faculty Development (CAPES).

Worldwide, the number of scientific articles on these topics rose by 498% in the same period.

“Thousands of scientists around the world are pursuing all kinds of applications for graphene – in transistors, for example, or DNA analysis, batteries, composites, and so on. More than 10,000 patents relating to applications have been registered,” said Professor Andre Geim, from Manchester University (UK). Geim won the Nobel Prize for Physics in 2010 with Russian physicist Konstantin Novoselov for discovering and isolating graphene. They first published their method in 2004.

Geim visited Brazil to attend the opening of MackGraphe. While there, he was awarded an honorary doctorate by UPM.

“Applications of graphene and other 2D materials will inevitably happen in different areas, as has already been the case with other materials like silicon and plastic, because now we know these materials and their fantastic properties,” Geim said.

Republish

The Agency FAPESP licenses news via Creative Commons (CC-BY-NC-ND) so that they can be republished free of charge and in a simple way by other digital or printed vehicles. Agência FAPESP must be credited as the source of the content being republished and the name of the reporter (if any) must be attributed. Using the HMTL button below allows compliance with these rules, detailed in Digital Republishing Policy FAPESP.