Image: Bioreset

A startup supported by FAPESP has developed an alternative material using waste from the beer production process and used cooking oil.

A startup supported by FAPESP has developed an alternative material using waste from the beer production process and used cooking oil.

Image: Bioreset

By Roseli Andrion | Agência FAPESP – Conventional plastic is one of the most widely used materials in the world and one of the hardest to decompose in nature, taking up to 450 years to disintegrate. The Brazilian startup Bioreset has developed a sustainable alternative: 100% biodegradable bioplastic produced from agricultural waste.

Bioreset’s creation has one crucial difference from polypropylene (PP), one of the most widely used petroleum-based plastics in the world: it is totally biodegradable. “It disappears completely in just six months,” says Carlos Sassano, the food engineer and researcher responsible for the project. Meanwhile, conventional plastic products, such as those made from polypropylene, remain intact for centuries. “When we say it lasts 450 years, it’s because they haven’t left any more time to test it. It could last even longer.”

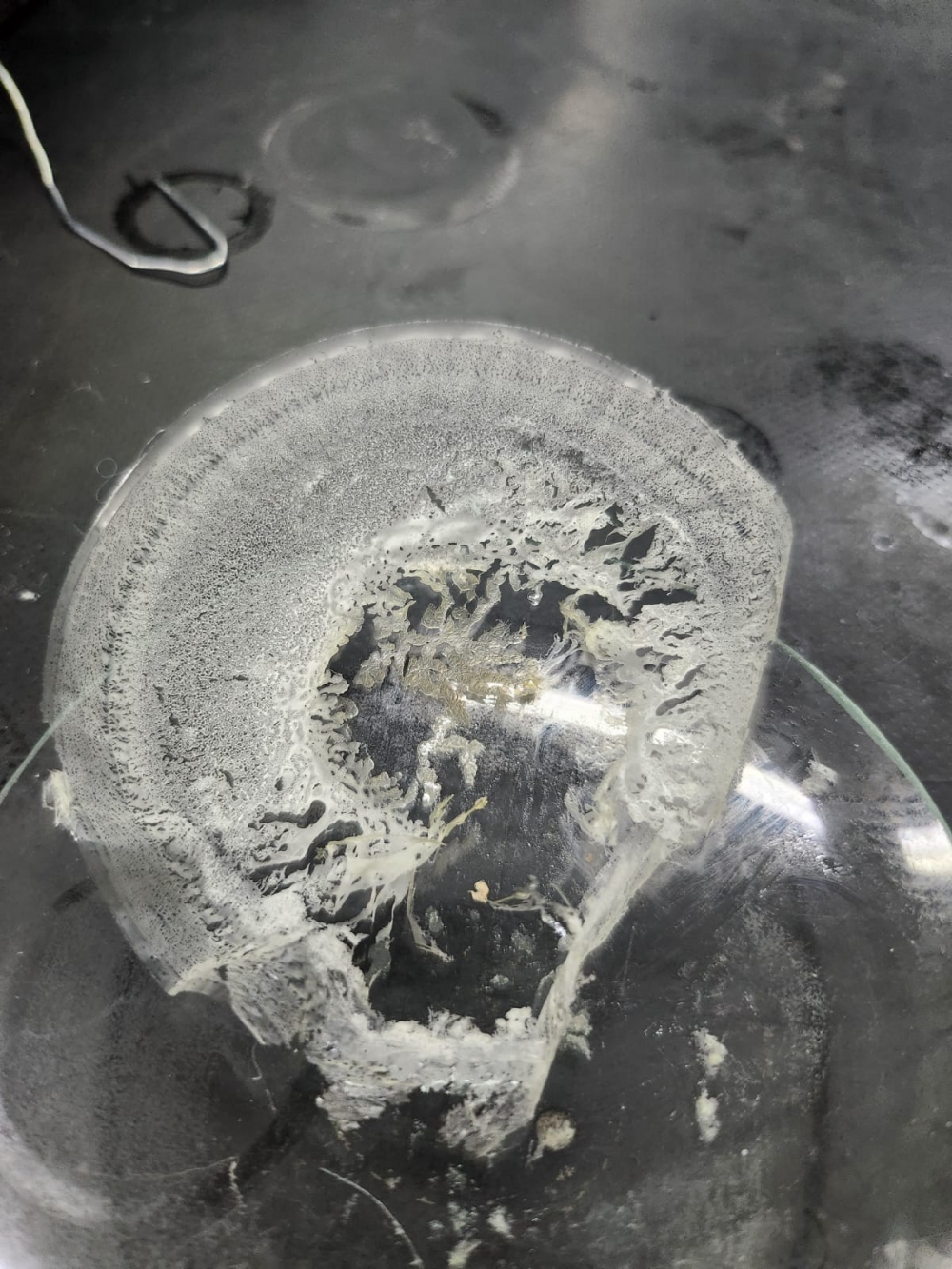

He explains that the material, called polyhydroxyalkanoate (PHA), is produced through a fermentation process using microorganisms. “We provide all the conditions for this microorganism to grow and accumulate PHA inside the cell. Then, we break up the cell, dry the material, and it becomes pellets to be used in various applications,” he explains.

Another one of the startup’s innovations is using waste such as raw material for fermentation, primarily of beer and used cooking oil. “This approach reduces production costs, making the product more competitive, and also solves two environmental problems: the improper disposal of this waste and conventional plastic,” he reveals.

Sassano points out that this waste undergoes protocols that make it suitable for human use without posing health risks. And much of this raw material is provided to the startup free of charge. “Many companies paid us to take the waste. More than half of the PHA we produced came from this material. This reduced the final cost significantly.”

Main features

Although the alternative made from PHA retains all the desirable characteristics of conventional plastic during its useful life, it is able to biodegrade completely. “It’s 100% biodegradable because it’s organic. Therefore, it can be disposed of with organic waste and turns into biocompost, which can be used as fertilizer,” says Sassano.

Bioreset’s initial focus is on single-use plastics, such as straws and coffee stirrers, which have a short lifespan yet remain in the environment for centuries. “There are items that will have to continue to be made of plastic, but single-use plastic is a big problem,” he points out. “For this type of application, this alternative helps to avoid contaminating the environment.”

For comparison, a conventional polypropylene coffee stirrer is used for a few minutes and then remains in the environment for up to 450 years. The same product made of PHA, however, disappears completely within four to six months after disposal. “The material only biodegrades when exposed to biodegradable conditions, such as humidity and the microorganisms present in soil.”

One of the biggest environmental problems related to conventional plastics is the formation of microplastics – fragments smaller than 5 millimeters derived from the breakdown of larger pieces. “They contaminate water, air, and soil, and they can be ingested by animals and humans,” says the researcher.

Unlike alternatives such as oxybiodegradables (plastics with additives that speed up the degradation process, but do not break down completely into organic compounds) or photodegradables (which break down more quickly under sunlight, which makes degradation faster than in ordinary plastic), which fragment into microplastics, PHA breaks down completely.

According to Sassano, research shows that a person can accumulate around 5 grams of microplastics in their body every year. “In ten years, you have the equivalent of a credit card in your body,” he warns. Bioreset’s plastic eliminates this risk by decomposing completely without leaving any residue in the environment.

Brazilian pioneering spirit

Although the technology for producing PHA is not new – PHB Industrial S.A. (PHBisa) was already working with this material in Brazil about 60 years ago – Bioreset has innovated by producing it from waste. “Sixty years ago, there wasn’t so much plastic material accumulating in the environment. That’s why there was no market maturity for PHBisa’s proposal.”

The company developed a protocol for using tailings as a substrate, making it a pioneer in Brazil and one of the first in the world to use this approach. The company has already carried out successful tests to inject the material into conventional equipment. “We don’t need to change the equipment: we do it exactly as we do with petroleum plastic. That’s a big advantage,” he says. Bioresets project is supported by FAPESPs Innovative Research in Small Businesses program (PIPE).

The startup now wants to purchase a 200-liter fermenter. “Today, we have a 7.5-liter fermenter. With larger equipment, we’ll be able to start serving the market in just two and a half months,” he estimates. According to him, Bioreset is the first Brazilian company to produce PHA from waste on a commercial scale.

Future and challenges

The startup has already garnered interest from large companies such as Ambev and Suzano, which see bioplastic as a solution to reduce their environmental impact. The challenge now is to increase production to meet demand. “Our protocols are all ready. Now we need investment to increase production capacity.”

In addition to waste beer and cooking oil, the company has protocols for using other agro-industrial waste, such as vegetable fibers. This will expand the possibilities for using materials that would otherwise be discarded. The company has at least five different protocols for different waste, demonstrating the versatility of the process.

Although Bioreset’s PHA is primarily valued for its biodegradability, the material is also recyclable, much like conventional plastics. “Its most important property is its biodegradability, but it’s also recyclable. This brings sustainability full circle,” says Sassano.

Bioreset hopes to significantly reduce the environmental impact of plastics with this technology by offering an alternative that allows for a complete “reset” of the plastic material cycle in nature. After use, the material returns to nature without leaving a trace. “It’s a product that represents an important step forward for the circular economy and environmental preservation.”

Republish

The Agency FAPESP licenses news via Creative Commons (CC-BY-NC-ND) so that they can be republished free of charge and in a simple way by other digital or printed vehicles. Agência FAPESP must be credited as the source of the content being republished and the name of the reporter (if any) must be attributed. Using the HMTL button below allows compliance with these rules, detailed in Digital Republishing Policy FAPESP.