Artificial muscle is 85 times stronger than its human counterpart

An international group of researchers, including five Brazilians, develops paraffin-coated carbon nanotube fibers.

Artificial muscle is 85 times stronger than its human counterpart

An international group of researchers, including five Brazilians, develops paraffin-coated carbon nanotube fibers.

An international group of researchers, including five Brazilians, develops paraffin-coated carbon nanotube fibers

By Elton Alisson

Agência FAPESP – A group of international researchers, including five Brazilians, has developed a yarn that is dozens of times stronger than an equivalent human muscle. The results of the study involving carbon nanotubes coated with paraffin, along with demonstration videos of the material, were published in Science magazine.

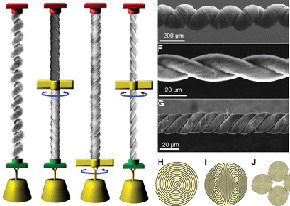

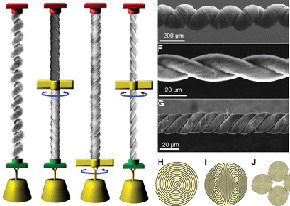

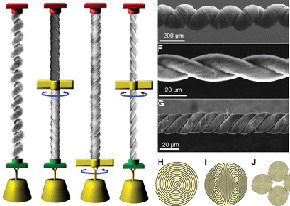

Like a wool thread, the material is formed by fibers comprised of carbon nanotubes – hollow cylindrical straws made up of carbon atoms occupying hexagonal vectors, which are light, conductive and dozens of times stronger than steel.

In the contracted state, the material was capable of developing a potency of 27.9 kW/kg, while the maximum a human muscle can withstand is 85 times lower. When twisted, the yarn forms a helicoidal structure and contracts entirely at a velocity of only 25 millionths of a second, which allows it to lift objects 100,000 times its weight.

Researchers observed that contraction of the yarn can be induced by a thermal stimulus that is produced by an electric current or light, because the material has a high capacity to absorb radiation and increase its own temperature to higher levels than others.

They also noted that contraction of the material could be enhanced if it is covered with paraffin, which can expand quickly when exposed to a heat source.

Through a combination of the properties of the two materials, when the thread is heated through exposure to an incandescent light bulb or an electric current, the paraffin coating expands, obliging the thread to contract. When it cools, the material returns to its original state, causing the yarn to relax, much like a human muscle.

“Because of the expansion and contraction of paraffin, the yarn can cyclically make this contraction and relaxation movement, which can be applied to lift objects much heavier than the material itself,” explains

Alexandre Fontes da Fonseca, professor at the Department of Physics at Universidade Estadual Paulista’s Sciences School, and one of the authors of the study, in an interview with Agência FAPESP.

According to the authors of the study, one of the possible technological applications of paraffin-coated nanotube fibers would be the development of intelligent fabrics that could offer protection against fire.

Because the yarn has the capacity to contract instantly in response to increased temperature, in an explosion, a fabric made with such a material could close its pores rapidly and impede fire exposure.

The material could also be used to develop “artificial muscles” to control the movements of external prosthesis (exoskeletons) and robots, to create more efficient levers to move objects, and to produce more effective catheters that could be used for minimally invasive interventions such as unclogging arteries.

One of the main possible uses for the material is for military applications in devices that can protect soldiers, for example, from ballistics. The main funders of the study in the United States were the Marines and the Air Force.

“This material will probably generate dozens of patents,” said

Douglas Soares Galvão, professor of the Gleb Wataghin Physics Institute at Universidade Estadual de Campinas (IFGW- UNICAMP) and author of the study.

This was not the first time that carbon nanotubes have been used to make a thread. A previous study conducted by the same group developed a thread that instead of being coated in paraffin needed a liquid or electrolytic source to work. As a result of this, however, the lightweight advantage of carbon nanotubes was lost because a heavy source was required.

“The major advance of this new paraffin-coated carbon nanotube fiber is that it can operate in the open air without any external source. Light is enough to make it contract,” comments Galvão.

For more than 20 years, Galvão has participated in scientific collaboration with scientists from the University of Texas at Dallas NanoTech Institute, where a research group including Brazilian participants Márcio Dias Lima and Mônica Jung de Andrade – the main authors of the study – conducted the experimental part of the study.

The other Brazilian authors of the study, Leonardo Dantas Machado, who is pursuing a doctorate at IFGW-UNICAMP under Galvão’s mentorship and through a FAPESP fellowship, and Fonseca, from UNESP in Bauru, who also completed scientific initiation, a doctorate and a post-doctorate with FAPESP fellowships – have also worked at the NanoTech Institute.

Brazilian Contribution

One of the main contributions of the Brazilian researchers to the study was the analysis of the structural, mechanical and elastomechanical properties of carbon nanotube fibers. Fonseca’s work, for example, was to better understand the formation process of the helicoidal structure of carbon nanotube fibers when they are twisted.

The objective of the study was to increase understanding about carbon nanotube fiber contraction on an individual scale. However, the group of scientists is still unsure whether carbon nanotubes undergo negative thermal contraction or expansion.

In the case of graphene, for example, which consists of flat carbon nanotubes, some studies show that when heated to less than 700 degrees, the material shrinks instead of expanding due to the vibration of atoms outside the structural plane. “There are still doubts about whether individual nanotube fibers contract or not, and a definitive conclusion cannot yet be made about this,” commented Fonseca.

Through a research project that he began in September with FAPESP funding, the researcher intends to study the thermal performance of the contraction and expansion of individual carbon nanotubes at a microscopic level through atomic simulations in an attempt to understand the mechanical and elastic properties of the thread.

The article

Electrically, chemically, and photonically powered torsional and tensile actuation of hybrid carbon nanotube yarn muscles (doi: 10.1126/science.1226762), by Márcio Dias Lima and others, can be read by subscribers of Science magazine at

www.sciencemag.org.