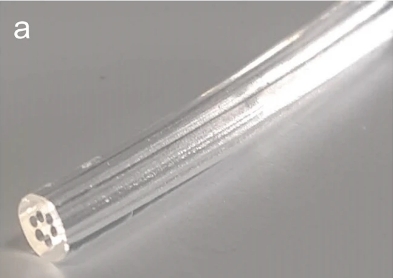

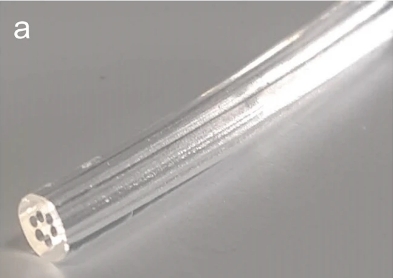

Edible, biocompatible and biodegradable, these fibers have potential for various medical applications. The results are described in the journal Scientific Reports (image: Scientific Reports)

Edible, biocompatible and biodegradable, these fibers have potential for various medical applications. The results are described in the journal Scientific Reports.

Edible, biocompatible and biodegradable, these fibers have potential for various medical applications. The results are described in the journal Scientific Reports.

Edible, biocompatible and biodegradable, these fibers have potential for various medical applications. The results are described in the journal Scientific Reports (image: Scientific Reports)

By José Tadeu Arantes | Agência FAPESP – An optical fiber made of agar has been produced at the University of Campinas (UNICAMP) in the state of São Paulo, Brazil. This device is edible, biocompatible and biodegradable. It can be used in vivo for body structure imaging, localized light delivery in phototherapy or optogenetics (e.g., stimulating neurons with light to study neural circuits in a living brain), and localized drug delivery. Another possible application is the detection of microorganisms in specific organs, in which case the probe would be completely absorbed by the body after performing its function.

The research project, which was supported by FAPESP, was led by Eric Fujiwara, a professor in UNICAMP’s School of Mechanical Engineering, and Cristiano Cordeiro, a professor in UNICAMP’s Gleb Wataghin Institute of Physics, in collaboration with Hiromasa Oku, a professor at Gunma University in Japan.

An article on the study is published in Scientific Reports, an online journal owned by Springer Nature.

Agar, also called agar-agar, is a natural gelatin obtained from marine algae. Its composition consists of a mixture of two polysaccharides, agarose and agaropectin. “Our optical fiber is an agar cylinder with an external diameter of 2.5 millimeters [mm] and a regular inner arrangement of six 0.5 mm cylindrical airholes around a solid core. Light is confined owing to the difference between the refraction indices of the agar core and the airholes,” Fujiwara told Agência FAPESP.

“To produce the fiber, we poured food-grade agar into a mold with six internal rods placed lengthwise around the main axis,” he continued. “The gel distributes itself to fill the available space. After cooling, the rods are removed to form airholes, and the solidified waveguide is released from the mold. The refraction index and geometry of the fiber can be adapted by varying the composition of the agar solution and mold design, respectively.”

The researchers tested the fiber in different media, from air and water to ethanol and acetone, concluding that it is context-sensitive. “The fact that the gel undergoes structural changes in response to variations in temperature, humidity and pH makes the fiber suitable for optical sensing,” Fujiwara said.

Another promising application is its simultaneous use as an optical sensor and a growth medium for microorganisms. “In this case, the waveguide can be designed as a disposable sample unit containing the necessary nutrients. The immobilized cells in the device would be optically sensed, and the signal would be analyzed using a camera or spectrometer,” he said.

The article “Agarose-based structured optical fiber” can be read at: www.nature.com/articles/s41598-020-64103-3.

Republish

The Agency FAPESP licenses news via Creative Commons (CC-BY-NC-ND) so that they can be republished free of charge and in a simple way by other digital or printed vehicles. Agência FAPESP must be credited as the source of the content being republished and the name of the reporter (if any) must be attributed. Using the HMTL button below allows compliance with these rules, detailed in Digital Republishing Policy FAPESP.